Shrink film has emerged as a versatile and effective packaging solution widely utilized across various industries. This innovative material, characterized by its ability to tighten and conform tightly around products when heat is applied, offers a range of benefits that enhance product protection, presentation, and performance. From securing items during transit to improving shelf life and minimizing waste, shrink film plays a crucial role in modern packaging strategies.

One of the primary advantages of shrink film is its adaptability. It can accommodate an array of products, varying in size and shape, making it an ideal choice for packaging both small consumer goods and large industrial items. Furthermore, shrink film provides a tamper-proof seal that assures product integrity, an essential factor for businesses prioritizing quality and safety. With these characteristics, shrink film not only supports brand aesthetics but also helps in optimizing logistics and distribution processes, making it an indispensable tool in the packaging landscape.

As we delve into the top ten uses and benefits of shrink film, it's clear that this packaging solution is not just a trend, but a fundamental component of efficient supply chains. Understanding its applications and advantages can empower businesses to make informed decisions that enhance their packaging efficiency and overall market competitiveness.

Shrink film is a versatile packaging material that has gained popularity across various industries. Defined as a plastic film that shrinks to fit the contours of an object when heat is applied, shrink film offers a secure and protective barrier for the items it encases. This unique property makes it ideal for wrapping products, ensuring they remain intact during handling, storage, and transportation.

There are different types of shrink films available, each suited for specific applications. The most commonly used types include PVC (Polyvinyl Chloride), polyethylene, and polyolefin films. PVC shrink film is often favored for its clarity and ability to conform tightly around products, making it perfect for retail packaging. Polyethylene shrink film, known for its durability and cost-effectiveness, is commonly used in bulk packaging, while polyolefin shrink film is recognized for its versatility and is suitable for both food and non-food items.

Understanding these types helps businesses select the right shrink film that aligns with their packaging needs, ensuring product safety and visibility on the shelves.

Shrink film has gained immense popularity in the packaging industry due to its versatile and protective qualities. One of the key benefits of using shrink film in packaging is its ability to provide a tight, secure wrap around a variety of products. This characteristic ensures that items are protected from dust, moisture, and potential physical damage during transit and storage. The snug fit of shrink film minimizes movement, which is particularly beneficial for irregularly shaped items, offering additional security compared to traditional packaging methods.

Another significant advantage of shrink film is its clarity and aesthetic appeal. The transparent nature of the film allows the product to be showcased while remaining protected, making it an ideal choice for retail environments. This visibility can enhance product presentation and attract customer attention, ultimately driving sales. Additionally, shrink film is lightweight, which contributes to cost savings in shipping and reduces the overall environmental impact associated with heavier packaging alternatives. Its ability to be easily applied through heat application further adds to its efficiency and effectiveness in various packaging scenarios.

Shrink film is a versatile packaging solution widely used across various industries due to its unique properties and benefits. One of the most common applications of shrink film is in food packaging. Its ability to form a tight seal around products not only extends shelf life by protecting against moisture and contaminants but also enhances presentation. Shrink film helps to maintain freshness and is ideal for packaging meat, dairy, and baked goods, enabling retail products to retain their quality while also showcasing them attractively on store shelves.

In addition to food packaging, shrink film is extensively utilized in the manufacturing and distribution sectors. It is commonly used to bundle multiple items together, such as boxes or pallets, providing stability during transportation and storage. This application is particularly beneficial for warehouses and shipping companies, as the durable nature of shrink film prevents items from shifting or becoming damaged in transit. Moreover, its clarity allows for easy visibility of barcodes and labeling, facilitating efficient inventory management. Overall, the diverse applications of shrink film across industries highlight its importance as a reliable and effective packaging solution.

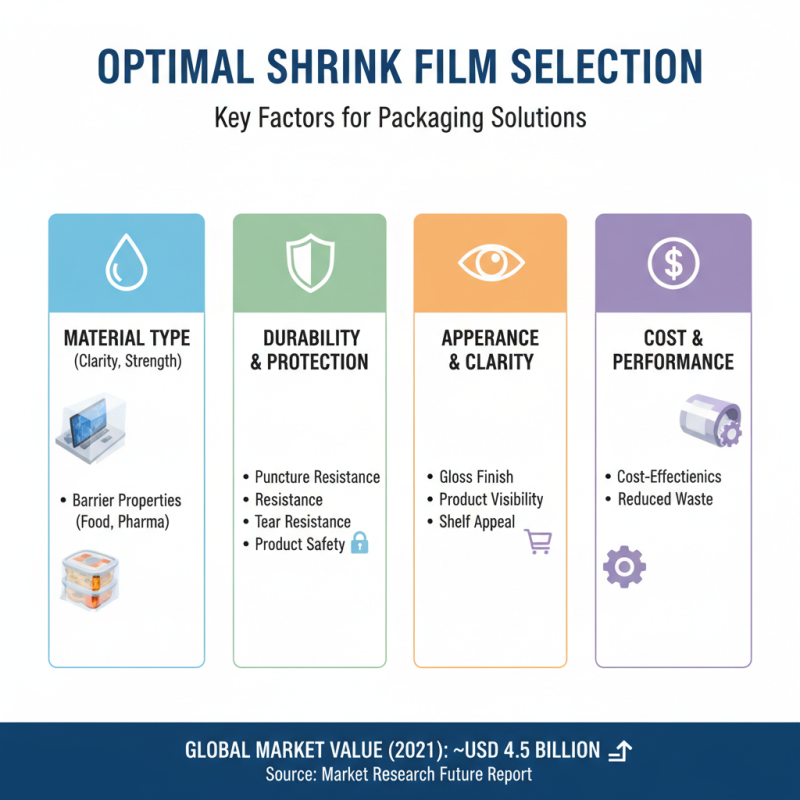

When selecting shrink film for packaging solutions, several critical factors come into play to ensure optimal performance and cost-effectiveness. One primary consideration is the type of material used in the shrink film, as different materials offer varying levels of barrier properties, durability, and appearance. According to a report from Market Research Future, the global shrink film market was valued at approximately USD 4.5 billion in 2021, underscoring the importance of selecting a film that meets specific needs. For instance, polyolefin shrink film is preferred for its clarity and strength, making it suitable for a wide range of products from food to electronics.

Additionally, the thickness of the shrink film can significantly impact its functionality. Thicker films generally offer better puncture resistance and sealing capabilities, which is crucial for ensuring product integrity during shipping and handling. The same industry report highlights that packaging films with thicknesses ranging from 40 to 75 microns are among the most commonly used, depending on application needs. It is also essential to consider the shrinkage ratio and testing standards, as they can affect the fit and presentation of the packaged products. Ultimately, an informed decision on these factors can lead to enhanced product protection, aesthetic appeal, and cost savings.

Shrink film is an excellent choice for packaging due to its versatility and effectiveness in protecting products. To achieve the best results in shrink wrapping, it's essential to adhere to best practices that optimize both the process and the end result. According to a market report by Smithers Pira, the global shrink film market is expected to reach $9.5 billion by 2025, highlighting its growing importance in various industries.

One critical technique is to ensure that the film is the right type and thickness for the product being wrapped. Thicker films provide better puncture resistance, while thinner films offer better shrink capability. It’s also vital to properly preheat the shrink tunnel settings according to the material being used, as uneven heating can lead to shrinkage issues. Also, ensure that the items are well arranged before wrapping; this facilitates even distribution of heat and minimizes any shrink-related imperfections.

Tips for effective shrink wrapping include conducting regular maintenance on the sealing equipment to prevent malfunctions and ensuring a clean working environment to avoid any contamination of the wrapped products. Additionally, investing in high-quality shrink film can yield significant long-term savings by reducing waste and enhancing the aesthetic appeal of the packaged product. This not only improves shelf presence but can also boost consumer confidence in the quality of the product inside.

| Use/Benefit | Description | Best Practice Tip |

|---|---|---|

| Product Protection | Shield products from dust, dirt, and moisture. | Ensure full coverage of the product for maximum protection. |

| Tamper Evidence | Shrink film can indicate tampering, enhancing security. | Use printed film for added visual tamper evidence. |

| Cost-Effective | Minimizes packaging costs while providing high-quality protection. | Choose the correct thickness of film for your products. |

| Sustainability | Many shrink films are recyclable and environmentally friendly. | Opt for biodegradable options when available. |

| Versatility | Can be used for various products across multiple industries. | Test different films for the best fit for your products. |

| Custom Branding | Can be customized with logos and graphics for branding. | Use high-quality printing techniques for visibility. |

| Enhanced Display | Creates a neat and tidy appearance for retail display. | Utilize clear films for better product visibility. |

| Space Saving | Reduces the amount of packaging materials needed. | Consider bundling products together to save space. |

| Speed of Packaging | Automated shrink wrapping can increase packaging efficiency. | Invest in quality, fast equipment to enhance production rates. |

| Temperature Resistance | Resistant to temperature variations during transport. | Select films suited for both hot and cold conditions based on your needs. |