Stretch film is an indispensable tool in the realms of storage and packaging, offering a versatile solution that caters to a myriad of needs across various industries. Its unique properties, including elasticity and durability, make it ideal for securing items together, protecting them from dust and moisture, and ensuring they remain intact during transportation. Whether you are a business owner looking to optimize your logistics or a homeowner aiming to organize your belongings efficiently, utilizing stretch film can greatly enhance your packaging strategy.

In this guide, we will explore the ultimate tips for using stretch film effectively, highlighting its advantages and versatility. From the different types of stretch film available to the best practices for application, readers will gain valuable insights into how to maximize the benefits of this essential material. Understanding the proper techniques for handling and storing stretch film will not only streamline your packing processes but also contribute to cost savings and sustainability.

Join us as we delve into the world of stretch film and uncover the secrets to achieving optimal storage and packaging solutions tailored to your unique requirements. With the right knowledge and approach, you can transform your packaging endeavors into a seamless and efficient operation.

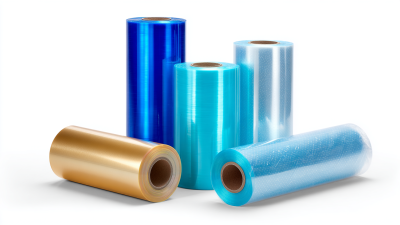

Stretch film is an essential tool in the world of storage and packaging, offering remarkable versatility for a variety of applications. Made of linear low-density polyethylene (LLDPE), this highly elastic material can stretch over items to secure them tightly while maintaining its shape. Stretch film is commonly used in both industrial settings for pallet wrapping and in personal storage to protect belongings from dust, moisture, and damage. Understanding its properties and uses can greatly enhance your packaging efficiency.

When utilizing stretch film, one key tip is to ensure the proper tension while wrapping. Stretching the film too tightly can lead to breakage, while too loose of a wrap can result in items shifting during transit. It's advisable to perform a test wrap to find the right balance for your specific items. Additionally, consider using colored stretch film to enhance visibility and organization within your storage areas. This can help easily identify different items and prevent mix-ups, especially in environments where multiple products are stored together.

Moreover, using different thicknesses of stretch film can cater to varying needs. Thicker films provide more protection for heavier loads, while thinner films can be cost-effective solutions for lighter items. Experimenting with these options will allow you to find the best fit for your storage or packaging requirements, ensuring that your items are well-protected and efficiently organized.

When selecting the right type of stretch film for packaging and storage, it’s essential to consider several key factors that can significantly affect performance and efficiency. According to industry reports, the global market for stretch film is projected to reach approximately $10 billion by 2025, driven largely by its versatile applications in various sectors, including food, textiles, and logistics. This forecast underscores the importance of understanding the diverse types of stretch films available, each designed to meet specific needs.

There are several types of stretch films, including hand stretch film, machine stretch film, and pre-stretched film. Hand stretch film is ideal for smaller, manual packaging operations and provides excellent puncture resistance while allowing for easy application. On the other hand, machine stretch film is designed for use on high-speed packaging machinery, increasing efficiency and reducing waste. Pre-stretched film, which is stretched during the manufacturing process, offers a thinner design with comparable load-holding strength, making it a cost-effective choice for reducing material usage while maintaining load integrity. As a result, businesses can optimize their packing processes and enhance protection for their products, aligning with the industry trend towards both sustainability and efficiency.

Stretch film is an incredibly versatile material that excels in various packing applications. To maximize its utility, proper techniques must be employed. First, it’s essential to choose the right gauge of stretch film based on the items being wrapped. For lightweight items, a thinner gauge may suffice, while heavier or bulkier products will require a thicker, sturdier film to ensure adequate protection and security. Additionally, ensure that the film layer overlaps sufficiently to create a tight and secure wrap, which will help prevent the load from shifting during transport or storage.

Another vital technique in utilizing stretch film effectively is mastering the application method. Start by securing one edge of the film to the item or pallet, then begin to wrap in a circular motion, gradually moving upward or downward, depending on the item’s shape. Consistent tension is crucial; too tight can lead to tearing, while too loose may not provide the required stability. Employing a dispenser can facilitate the wrapping process, allowing for easier handling and improved effectiveness in achieving a snug fit. By following these techniques, users can enhance their packaging solution, ensuring items remain intact and protected during storage and transit.

Stretch film has emerged as a pivotal element in enhancing storage solutions across various industries. According to a report by the Freedonia Group, the demand for stretch film is projected to reach $6.7 billion by 2024, driven primarily by its effectiveness in protecting products during storage and transportation. The unique properties of stretch film—such as its high elasticity and puncture resistance—allow it to securely wrap items of varying shapes and sizes, providing a customized fit that traditional packaging methods often lack.

In warehouses and distribution centers, stretch film plays a crucial role in optimizing storage space. A study by MarketsandMarkets indicates that stretch wrapping can increase storage density by up to 30%, as it minimizes the unused space typically caused by rigid packaging solutions. Furthermore, the transparent nature of stretch film allows for easy visibility of contents, which facilitates inventory management and reduces the likelihood of errors during stocktaking. By employing stretch film, businesses can not only improve their storage efficiency but also enhance the safety and integrity of their products during handling and shipment.

Stretch film is a widely used material in storage and packaging due to its flexibility and durability. However, the environmental impact of plastic waste, including stretch film, necessitates responsible recycling and disposal practices. One essential step is to ensure the film is clean and free from contaminants. Before recycling, remove any residues or materials that could interfere with the recycling process. Many facilities only accept stretch film that is free of food debris, labels, and other attached items.

To properly dispose of stretch film, check for local recycling programs that accept plastic films. Some areas have designated drop-off locations specifically for soft plastics, including stretch film. If recycling is not an option, consider reusing the film for future packing needs or as protective wrapping for items in storage. Being mindful of how we manage stretch film can significantly contribute to reducing landfill waste and promoting a healthier environment. Knowing these best practices equips individuals and businesses with the tools necessary to minimize their ecological footprint while still benefiting from the advantages of stretch film in storage and packaging.

| Tip Category | Best Practices | Recycling & Disposal |

|---|---|---|

| Storage Tips | Store rolls in a cool, dry place to prevent degradation. | Check local recycling programs for stretch film acceptance. |

| Application Techniques | Use consistent tension when wrapping to prevent load shifting. | Avoid mixing with non-recyclable materials when disposing. |

| Multi-Purpose Uses | Utilize for bundling items securely for shipping or storage. | Consider reusing clean stretch film before disposal. |

| Environmental Tips | Choose biodegradable options when available. | Follow local guidelines for plastic film recycling. |