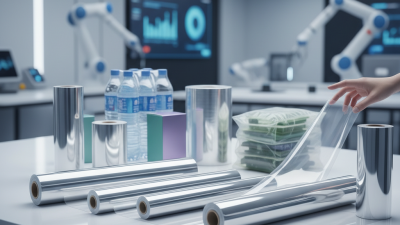

The packaging industry has seen significant advancements in materials and technologies over the years, with one innovative solution standing out: Cross-Linked Shrink Film. This versatile material has garnered attention for its impressive performance characteristics, making it an ideal choice for a myriad of applications across various sectors. As we look towards 2025, understanding the benefits and trends associated with Cross-Linked Shrink Film is crucial for manufacturers and businesses aiming to enhance their packaging strategies.

In the rapidly evolving landscape of product packaging, Cross-Linked Shrink Film offers distinct advantages, such as improved strength, durability, and resistance to environmental factors. These properties not only extend the shelf life of products but also enhance the overall aesthetic appeal, making it a preferred choice for brands looking to captivate consumers. Additionally, the rise of sustainability in packaging has prompted innovations within the realm of Cross-Linked Shrink Film, as manufacturers explore eco-friendly options that do not compromise on quality or performance.

Moreover, as market demands evolve, the applications of Cross-Linked Shrink Film are set to expand further. From food and beverage packaging to consumer goods and industrial applications, the versatility of this material is undeniable. This introduction aims to delve deeper into the current and future uses of Cross-Linked Shrink Film, exploring the benefits it offers and the trends that will shape its future in the marketplace.

In 2025, cross-linked shrink films are set to revolutionize several key industries, with prominent applications spanning from packaging to construction. Notably, the food and beverage sector is projected to be among the largest users of these films, driven by an increasing demand for superior product protection and shelf life extension. According to a recent market analysis report, the global market for shrink films is expected to reach $11 billion by 2025, with cross-linked options accounting for a significant segment due to their durability and thermal properties.

The pharmaceutical and healthcare industries are also expected to leverage cross-linked shrink films extensively. Their resistance to punctures and tears enables safe and reliable packaging for sensitive products, which is vital for maintaining compliance with stringent regulatory standards. Insights from industry experts indicate that the adoption of cross-linked films in these sectors could enhance supply chain efficiency by up to 20%, significantly reducing operational costs.

**Tip:** When utilizing cross-linked shrink films, ensure that the sealing temperatures are adjusted according to the specific materials to achieve optimal shrinkage and adherence.

Furthermore, the e-commerce sector is witnessing a surge in cross-linked shrink film applications, driven by the need for robust packaging solutions that can withstand the rigors of shipping and handling. Reports suggest that the integration of these films in packaging could improve product integrity during transit, addressing consumer safety concerns effectively.

**Tip:** Consider using clear cross-linked shrink films to allow consumers to view the product, enhancing the overall shopping experience while providing necessary protection.

Cross-linked shrink films have emerged as a pivotal choice in product packaging due to their superior properties that significantly enhance product protection and presentation. One of the key benefits of these films is their exceptional strength and durability. The cross-linking process creates a three-dimensional polymer network, resulting in films that are less prone to punctures and tears. This robustness ensures that products remain intact during handling and transportation, reducing the likelihood of damage and spoilage.

Another major advantage of cross-linked shrink films is their excellent shrink characteristics. When heat is applied, these films contract uniformly, providing a tight and secure fit around various products. This not only enhances the visual appeal of the packaging but also improves shelf life by minimizing exposure to environmental factors such as moisture and dust. Moreover, the ability to conform to irregular shapes makes cross-linked shrink films a versatile option for a wide range of applications, from food packaging to consumer goods, thereby meeting the diverse needs of manufacturers and consumers alike.

The emerging trends in cross-linked shrink film technology for 2025 indicate a significant shift toward enhanced performance and sustainability. With growing environmental concerns, manufacturers are increasingly focusing on bio-based materials and recyclable formulations. These innovations not only reduce the environmental impact but also cater to the rising consumer demand for eco-friendly packaging solutions. Furthermore, advancements in polymer technology are enabling the production of films that exhibit superior tensile strength, heat resistance, and clarity, making them suitable for a wider range of applications.

Additionally, automation and smart technology integration are becoming essential in the production and application of cross-linked shrink films. The use of IoT and AI in monitoring and optimizing manufacturing processes is helping to reduce waste and improve efficiency. Such technologies allow for real-time adjustments during the production cycle, ensuring that the films are produced to precise specifications while minimizing defects. As businesses strive for operational excellence, these advancements will not only enhance product quality but also streamline supply chain processes, setting the stage for a more efficient and economically viable future in the shrink film market.

The market for cross-linked shrink films is anticipated to witness significant growth by 2025, fueled by the increasing need for durable and high-performance packaging solutions across various sectors. As industries strive for enhanced product protection and appealing presentation, cross-linked shrink films stand out due to their superior strength and resistance to tearing. This durability makes them ideal for packaging sensitive goods, ranging from food items to pharmaceuticals, ensuring that products remain intact during storage and transportation.

Moreover, the trend towards sustainability is expected to further accelerate the demand for cross-linked shrink films. Manufacturers are increasingly focusing on developing eco-friendly alternatives that not only meet performance standards but also minimize environmental impact. Innovative production techniques and the incorporation of recyclable materials into shrink film formulations are likely to resonate with environmentally conscious consumers. This shift towards sustainable practices, combined with robust market growth, positions cross-linked shrink films at the forefront of packaging solutions in the coming years.

The cross-linked shrink film sector is increasingly focusing on sustainability initiatives to align with global environmental goals. According to recent market insights, the demand for sustainable packaging solutions has surged, with the global eco-friendly packaging market projected to reach $500 billion by 2027. Many manufacturers are adopting biodegradable materials and recyclable options in their shrink films to reduce environmental impact.

Tips: When considering cross-linked shrink films for your packaging needs, look for suppliers that prioritize sustainability. Certifications such as FSC or ASTM D6400 indicate responsible sourcing and compostability, ensuring that your packaging contributes positively to the environment.

Additionally, the trend towards lightweight packaging is gaining traction, as it not only reduces material usage but also decreases transportation costs and emissions. By implementing energy-efficient production processes, companies can further enhance their sustainability efforts, with the potential to cut production energy consumption by up to 30%, as cited in a recent report by the Flexible Packaging Association.

Sustainability in the cross-linked shrink film industry is not just a trend but a necessary evolution for future growth.