Shrink Film Packaging is an effective method for protecting products during storage and transport. According to David Green, a well-known expert in the shrink film industry, “The right shrink film can make all the difference in product safety.” This insight highlights the importance of choosing the right materials for wrapping goods.

Using shrink film provides several benefits. It guards against dust, moisture, and physical damage. This is crucial for fragile items or electronics. However, the selection process can be overwhelming. Different types of films serve various purposes. A poor choice can lead to product loss or customer dissatisfaction. It's essential to assess the specific needs of the product before selecting a film.

While shrink film offers excellent protection, companies may overlook some details. For example, ensuring proper sealing is vital. An inadequate seal can render the film useless. It’s worth reassessing processes and training staff on best practices. This ensures products remain in perfect condition from production to delivery.

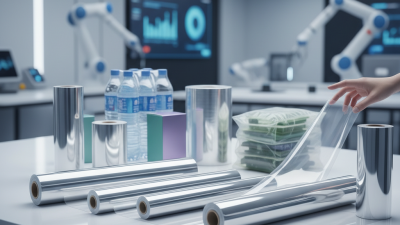

Shrink film is a versatile packaging material that provides excellent protection for various products. Different types of shrink film cater to different needs. The most common types include polyolefin, PVC, and polyethylene. Polyolefin is known for its clarity and strength, making it ideal for display packaging. PVC is often used for bundling items together, while polyethylene offers durability and flexibility.

Each type has specific applications. For instance, food packaging often relies on polyolefin due to its safety and barrier properties. On the other hand, PVC shrink film is great for toys and other retail products. Moreover, the choice of film must account for the product's shape and size. A simple mistake in sizing can lead to issues like leaks or insufficient protection. The right shrink film can enhance your product’s appeal while keeping it safe.

However, not all shrink films fit every application. It’s vital to test different options. Watch for issues like inconsistency and uneven sealing. These can undermine the packaging’s functionality. Reflecting on previous experiences can also help improve future packaging decisions.

Preparing your products for shrink film packaging requires careful attention to detail. Start by cleaning each product to remove any dust or residue. This simple step can greatly impact the final appearance. Consider the product size and shape—ensure no sharp edges could puncture the film. It's essential to have a precise fit.

Next, organize your products systematically. Lay them out in a way that facilitates easy access for wrapping. This can save time and reduce errors during packaging. If you’re bundling items, make sure they are similar in size. Variation can lead to uneven shrink wrapping, which might compromise protection.

Don’t forget to check your equipment before starting. Wrapping with malfunctioning machinery can result in poorly sealed packages. Test the settings with a sample product. Finally, review your packaging process regularly for areas of improvement. Over time, you'll find ways to enhance efficiency and ensure better product safety.

Shrink film packaging is an effective way to protect products. It’s versatile and widely used in various industries. With over 40% of companies reporting damage during transit, proper application of shrink film is crucial.

Start with choosing the right shrink film. Different thicknesses and types exist. For instance, low-density polyethylene (LDPE) is common but may not suit all products. Cut the film to size. Ensure it's slightly larger than your product. This helps in achieving a snug fit. Use a heat gun or shrink tunnel to apply heat evenly. Watch the temperature; too high can create holes, while too low might not shrink properly.

After shrinking, inspect the packaging. Look for air pockets or loose areas. These can lead to product damage. Studies show that improperly sealed packages increase return rates by up to 15%. It’s essential to test different methods. Experimenting helps identify the best approach for your product line. Consider customer feedback, as packaging experiences vary. This process requires patience and fine-tuning. Effective shrink film application ultimately enhances product appeal and safety.

Choosing the right equipment for shrink film sealing is crucial for effective product protection. In the packaging industry, reports indicate that about 70% of businesses utilize shrink film packaging for its durability and versatility. The right sealing machine can enhance the overall efficiency of the packaging process. Automated sealers can increase throughput significantly. However, operators must receive proper training to minimize errors.

There are several types of shrink film sealing equipment available. Manual sealers are budget-friendly but may slow down production. Semi-automated and fully automated machines provide faster sealing times. Research shows that automated systems can reduce labor costs by up to 30%. Choosing the right machine involves assessing production volume and product dimensions. Often, businesses overlook the importance of maintenance, leading to unexpected downtime.

Investing in high-quality sealing equipment may come with a higher upfront cost. However, the return on investment often justifies this expense. Issues like poor sealing can result from using inferior machines. Quality control is vital in these scenarios. Inadequate equipment can lead to wasted materials and increased overall costs. Companies must continuously evaluate their sealing processes to adapt to changing demands.

| Product Type | Shrink Film Material | Sealing Equipment | Heat Source | Recommended Use |

|---|---|---|---|---|

| Electronics | PVC Shrink Film | L-Bar Sealer | Heat Gun | Protect against moisture and dust |

| Food Items | Polyolefin Shrink Film | Automatic Sleeve Sealer | Heat Tunnel | Maintain freshness and presentation |

| Cosmetics | PET Shrink Film | Handheld Impulse Sealer | Heat Air Blower | Enhance product visibility and protection |

| Toys | Heavy Duty Shrink Film | Shrink Wrap Machine | Heat Chamber | Provide safety and visual appeal |

When storing and shipping shrink-wrapped products, proper techniques are essential.

The packaging secures items but requires careful handling. Before placing items in storage, ensure they are clean and dry. This reduces the risk of moisture damage. A climate-controlled environment is ideal, as extreme temperatures can affect the integrity of the shrink film.

During shipping, the choice of boxes and pallets matters. Use sturdy boxes that fit snugly around the shrink-wrapped products. Avoid overloading boxes, as this can lead to crushing. Pay attention to stacking; ensure that heavier items are at the bottom. This prevents damage and maintains stability during transit. Inspect products regularly for any signs of wear and tear on the shrink film; a small tear can lead to larger issues.

Communication with shipping partners is crucial. Provide clear guidelines for handling. Some workers may not understand the fragility of shrink-wrapped products. Regular training can help address this concern. It’s important to reflect on these practices and adjust accordingly. Over time, the process can improve, leading to better protection for your products.