In the shipping industry, the importance of proper packaging cannot be overstated. A recent report from the Packaging Institute reveals that nearly 30% of all shipping damages result from inadequate protective measures. This highlights the vital role of "Shrink And Wrap" techniques in ensuring items arrive safely. John Stokes, a leading expert in packaging solutions, asserts, "Effective shrink and wrapping can reduce product damage by up to 50%."

Shrink and wrap methods are crucial for various industries, especially in e-commerce. They ensure products remain intact during transit, protecting them from environmental factors. However, many still underestimate the necessity of using high-quality materials and proper techniques. Rushing the packaging process often leads to costly damages. Industry data indicates that businesses spend billions annually on shipping damages that could have been avoided.

While the process of shrink wrapping may seem straightforward, there are nuances to consider. Affordability and efficiency must be balanced with quality. Small businesses may risk using cheap materials, compromising safety. As we explore strategies for effective shrink and wrap techniques, it is essential to reflect on the importance of investing in durable solutions.

Proper packaging is crucial for safe shipping. It protects items from damage during transit. Whether you're sending fragile glass or clothing, the right materials matter. Poor packaging can lead to broken items and unhappy customers. Understanding how to shrink and wrap your items effectively can help prevent these issues.

One important tip is to choose appropriate packing materials. Bubble wrap and foam peanuts are great for fragile items. Use cushioning for delicate pieces. A simple cardboard box can protect many items, but make sure it’s sturdy enough. Don't skimp on tape. Weak tape can lead to boxes bursting open. Also, remember to seal all sides to keep contents secure.

Assessing the size of your items is also significant. If items are loose in their packaging, they can shift and get damaged. Sometimes, it’s necessary to wrap individual items before placing them in a box. However, this can take time. Experimenting with different packing methods can help you find what works best for you.

Finally, always label your packages clearly. A misplaced label can cause delays. Inadequate labeling can lead to items being sent to the wrong address. Small details like these are often overlooked, but they can make a huge difference in the shipping experience.

When it comes to shrinking and wrapping items for shipping, the choice of materials is crucial. Start by considering the size and shape of your items. Bubble wrap provides cushioning for fragile objects. It’s lightweight and ideal for delicate items such as glass or ceramics. Using a combination of different materials can enhance protection. Think about using packing paper or foam for added stability.

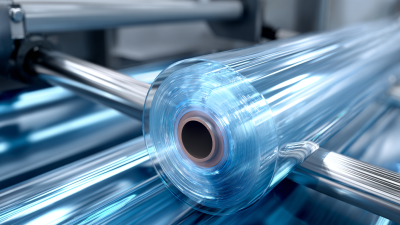

Shrink wrap is another effective option. It molds tightly around items when heat is applied. This creates a strong, protective barrier against moisture and dirt. However, remember that not all items are suited for shrink wrap. Complex shapes might require more careful wrapping techniques. It’s not as forgiving as other materials. Always keep in mind that over-wrapping can lead to an awkwardly bulky package.

Choosing the right tape is also important. A strong packing tape will help secure your wrapped items. However, it must comply with shipping guidelines. If you use too much tape, it can be difficult to unpackage later. Find a balance that protects while remaining user-friendly. Observing how your items fare during shipment can help you refine your approach in the future.

| Material Type | Usage Purpose | Benefits | Considerations |

|---|---|---|---|

| Shrink Wrap | Protecting items from moisture and dust | Forms a tight seal, enhances durability | Requires heat source for application |

| Bubble Wrap | Cushioning fragile items | Effective shock absorption | Bulky, may take more space |

| Packing Paper | Wrapping and filling empty spaces | Eco-friendly option, lightweight | Less protective for heavy items |

| Corrugated Boxes | Shipping a wide range of items | Sturdy and stackable | Requires additional cushioning for fragile items |

| Foam Wrap | Wrapping around sensitive electronics | Lightweight, excellent protection | Can be more costly than others |

When shipping items, shrink wrapping is a practical method for protection. To start, gather your materials. You'll need shrink wrap film, a heat gun, and a sturdy pair of scissors. Lay out the item on a clean, flat surface. Make sure there are no sharp objects around. Uneven surfaces can lead to wrinkles in the wrap.

Next, cut a piece of shrink wrap large enough to cover the entire item. Ensure an extra four to six inches on each side. Place the item in the center and fold the wrap over it. Remember to keep the wrap tight. After adjusting the wrap, use the heat gun to shrink the film. Move the heat gun evenly across the surface. Too much heat in one spot can create holes. Be cautious and patient; it’s easy to burn through the material.

Once the item is tightly wrapped, check for any loose areas. Reseal them using the heat gun. Packaging may look imperfect, but that’s okay. It’s about functionality, not just appearance. If there are air bubbles, gently poke them with a pin and reseal. Practice makes perfect. Each attempt will help improve your wrapping technique, ensuring safer shipping with less chance of damage.

When preparing items for shipping, securing them is critical. A report from the International Safe Transit Association (ISTA) reveals that about 10% of products are damaged during shipping. Proper wrapping can significantly reduce this risk. Using bubble wrap, or packing peanuts can cushion items and absorb shocks. These materials are not extremely expensive, but their impact is substantial.

Ensure all items are tightly wrapped. Loose packing allows movement within the box, leading to potential damage. A study by the Packaging Technology and Science journal emphasizes that properly secured items are 30% less likely to sustain damage. Don’t forget to seal boxes securely. Weak seals can fail and lead to an item falling out during transit, which creates a scenario for loss.

Some might think that just any tape will suffice, but that’s not true. Only use heavy-duty shipping tape. It adheres better and lasts longer. It may seem trivial, but it deserves attention. Measuring dimensions accurately is equally crucial. Misjudging size can lead to overcrowded boxes, increasing the chance of mishaps. As you wrap, reflect on these details, and assess room for improvement each time. Being meticulous today prevents future regrets.

When preparing items for shipping, labeling is crucial. Labels should be clear and legible. Use a readable font and appropriate size. Place the address in the center. Additional information can include tracking numbers. Avoid cluttering the label with too much detail. Simple is better.

Handling wrapped packages is another critical aspect. Ensure that the wrapping is secure. Use sturdy materials that can withstand rough handling. Fragile items need extra attention. Indicate "FRAGILE" on the label. It helps warehouse staff prioritize care. Sometimes, packages can still sustain damage despite labels. This is a reality we must acknowledge.

Regular reviews of your packaging process can identify gaps. Look at past shipments for patterns of issues. Are labels always clear? Is the wrapping adequately protecting items? Fine-tuning these elements can significantly enhance shipping reliability. Mistakes happen, but learning from them is key. Consider feedback from recipients as part of this improvement process.