Printing Film plays a crucial role in various industries today. This versatile material is used for producing high-quality graphics. It acts as a medium for transferring images, designs, and texts onto different surfaces.

In areas like packaging and advertising, Printing Film enhances visual appeal. Its ability to withstand various environmental factors makes it popular. However, not all Printing Films are created equal. Some films may not adhere well to certain substrates. This inconsistency can lead to quality issues. Companies must choose the right type cautiously.

While Printing Film serves many benefits, challenges exist. For instance, environmental concerns are rising. Finding eco-friendly alternatives is vital for sustainable practices. As industries evolve, so must the technologies behind Printing Film. Understanding these dynamics is essential for future developments.

Printing film is a crucial component in various industries, particularly in graphic arts and packaging. Its primary function is to transfer images or designs onto surfaces. This film is typically made from a variety of polymers and photo-sensitive materials. The composition can vary based on the specific requirements of a project. For instance, some printing films are designed to withstand high temperatures, while others may be more flexible for different applications.

According to industry reports, the global printing film market was valued at approximately $12 billion in 2022. The demand for high-quality packaging solutions, especially in food and pharmaceuticals, drives the growth of this market. Additionally, as sustainability becomes a priority, the industry is shifting towards biodegradable printing films. However, not all alternatives meet performance expectations. Some biodegradable options may not adhere properly or provide the necessary durability.

Moreover, the film’s production process can be quite complex. It often involves multiple layers, each with distinct attributes. These layers must interact seamlessly to produce the desired outcome. Challenges remain in balancing cost and quality. While innovations continue to emerge, companies frequently face difficulties in meeting evolving consumer demands. It raises questions about how to improve processes without compromising standards.

Printing films are crucial in various industrial applications. Different types are available, each with unique properties and uses. Common materials include polyester, polycarbonate, and vinyl. These films provide durability and versatility, making them ideal for products like labels, packaging, and graphics.

Polyester films are particularly popular. They possess high tensile strength and resistance to moisture. According to market reports, the global demand for polyester films is projected to reach $10 billion by 2025. However, not every application benefits from polyester’s rigidity. Some require flexible, soft films, where polycarbonate shines.

Vinyl films offer more options for creative designs. They come in many colors and finishes. A recent analysis indicated that vinyl films make up approximately 30% of the printing films market. However, their environmental impact raises concerns. Some vinyl films use harmful additives, prompting industry shifts toward eco-friendlier alternatives.

The quest for sustainability complicates material selection. Finding a balance between performance and environmental responsibility is challenging. Continuous research is needed to optimize the properties of these materials while minimizing their ecological footprint.

Printing film plays a crucial role in the packaging industry. It serves various applications, especially in food and beverage packaging. This material ensures products remain fresh and protected. Lightweight and flexible, printing films adapt easily to different shapes and sizes. They can be used in pouches, wrappers, or labels, making them versatile. Companies can print vibrant graphics directly on the film, attracting consumers’ attention.

In recent years, sustainability has become a vital concern. Some printing films use recyclable materials, which can help reduce waste. However, many industries still struggle to find a balance between functionality and eco-friendliness. Not all printing films are biodegradable. This inconsistency poses challenges for companies aiming to improve their environmental footprint.

Moreover, the quality of printing films can vary, leading to production issues. Some films may not adhere well during the printing process. This inconsistency can affect the final product's visual appeal. Businesses must evaluate their options carefully. The right choice can enhance both product visibility and consumer trust. Yet, many still overlook this critical step.

| Application Area | Type of Printing Film | Key Properties | Advantages |

|---|---|---|---|

| Flexible Packaging | Polyethylene (PE) Film | Lightweight, moisture-resistant | Cost-effective, recyclable |

| Labels and Tags | BOPP Film (Biaxially Oriented Polypropylene) | Crystal clear, durable | Excellent print quality, resistant to oils and chemicals |

| Shrink Sleeves | PVC Film (Polyvinyl Chloride) | High clarity, good shrinkability | Full coverage design, vibrant colors |

| Food Packaging | PET Film (Polyethylene Terephthalate) | Barrier properties, FDA approved | Extended shelf life, safe for food contact |

| Cosmetics Packaging | Metalized Film | Reflective, barrier properties against light | Luxury appeal, enhances shelf presence |

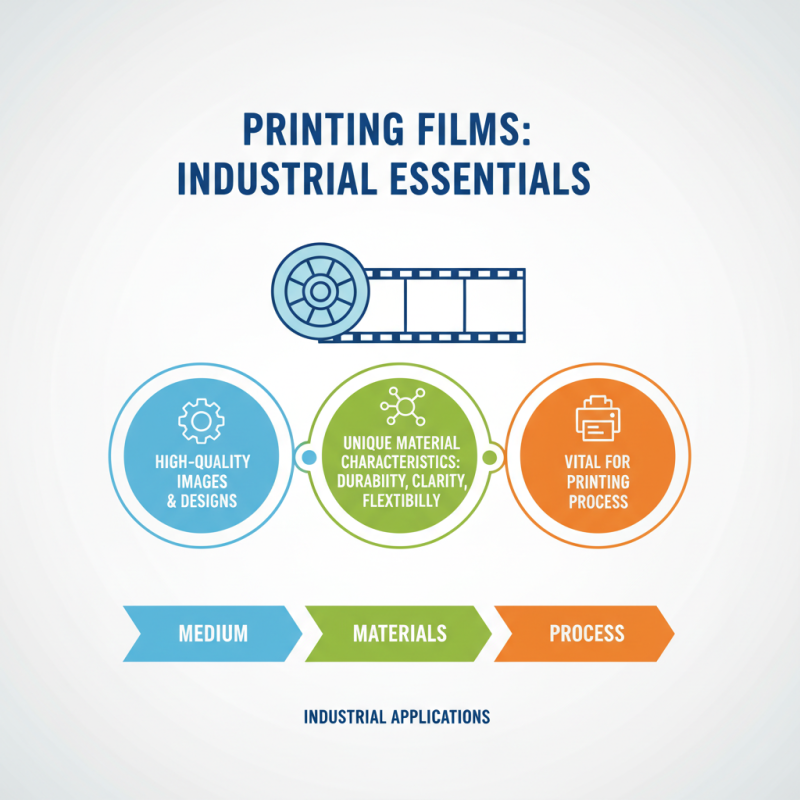

Printing films are essential in various industrial applications. They serve as a medium for producing high-quality images and designs. The materials used in these films provide unique characteristics. Their durability, clarity, and flexibility play a vital role in the printing process.

The technical specifications of printing films are crucial. Many films are made from polyester or other synthetic materials. These materials offer resistance to tearing and high temperatures. Light transmission is also a key property. High-quality films allow for vivid colors and sharp details. This ensures that the final printed product meets strict standards.

However, not all films are equally effective. Some may not adhere well to certain substrates, leading to poor results. It's essential to consider the compatibility between the film and the printing medium. Testing different films can lead to better outcomes. This trial-and-error approach can sometimes be frustrating but is necessary for achieving the best results.

Innovations in printing film technology are driving significant market growth. The global printing film market is expected to reach $XX billion by 2025, with a CAGR of XX%. Companies are increasingly adopting eco-friendly materials. These advancements aim to reduce waste while maintaining high-quality standards.

One notable trend is the use of nanotechnology in film coatings. This allows for better durability and print quality. However, not all manufacturers can adapt quickly. Some remain stuck with traditional methods, losing competitiveness. Industry analysts indicate that those who innovate will thrive, while others may lag behind.

Additionally, digital printing is reshaping the landscape. It reduces lead times and enhances customization. Yet, the transition can be costly for some businesses. Market reports suggest a 20% increase in companies adopting digital solutions in the next few years. Embracing change is essential, but not every company is ready to invest. The future of printing film rests on a delicate balance between innovation and practicality.