Plastic shrink wrap is a versatile and widely used packaging material known for its ability to tightly envelop products and provide protection during storage and transportation. As industry expert Dr. Emily Carter states, "Plastic shrink wrap not only safeguards items from environmental factors but also enhances the presentation and marketing appeal." This powerful statement underscores the multifaceted benefits of plastic shrink wrap that resonate across various sectors, including shipping, retail, and food service.

From wrapping pallets of goods to securing individual products, the applications of plastic shrink wrap are practically limitless. Its ability to conform closely to the contours of whatever it encases creates a sturdy and protective barrier, allowing for improved organization and space efficiency. Additionally, plastic shrink wrap aids in waste reduction by combining multiple items into a single bundle, minimizing the overall packaging requirements.

Choosing the right type of plastic shrink wrap can significantly impact its effectiveness and cost-efficiency. Factors such as thickness, clarity, and shrink rate must be considered for optimal performance. Understanding these elements is essential for businesses aiming to leverage plastic shrink wrap to its fullest potential, ensuring not only protection and preservation of goods but also a professional appearance that can enhance customer satisfaction.

Plastic shrink wrap is a versatile packaging material commonly used across various industries. It works by utilizing heat to shrink tightly around the items it covers, creating a secure and protective layer. When heated, the plastic film contracts, forming a snug fit around products, which helps safeguard them from dust, moisture, and tampering. This unique property is what makes shrink wrap an essential tool in packaging operations both for manufacturers and consumers.

According to industry reports, the global shrink wrap market is projected to grow by approximately 4.6% annually through 2025. This growth can be attributed to the rising demand for packaged goods and the growing e-commerce sector, where secure, protective packaging is critical. The benefits of using plastic shrink wrap include improved product visibility and tamper evidence, which are crucial for maintaining brand integrity and consumer trust. Additionally, the material is recyclable, contributing to sustainability efforts within the packaging industry.

**Tips:** When choosing the right type of shrink wrap, consider the thickness and type of film suitable for your specific application. Thicker films offer better puncture resistance, while thinner options can be more economical for lower-risk packaging. Always ensure the shrink wrap's compatibility with the items being packaged to maximize its protective qualities and minimize waste.

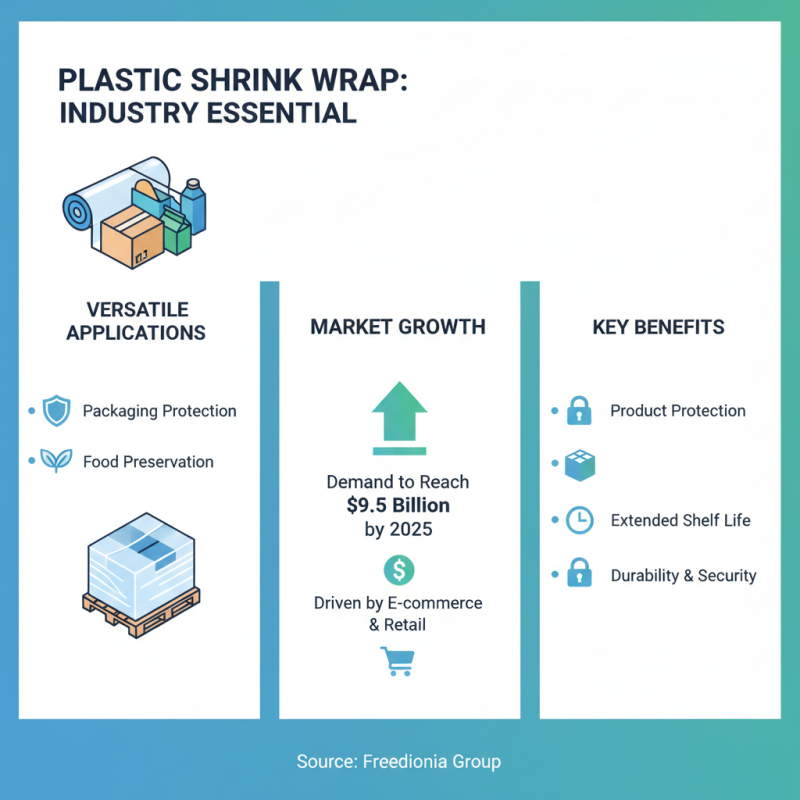

Plastic shrink wrap is an essential component across various industries, known for its versatile applications and benefits. In packaging, it provides a tight seal that protects products from external elements, ensuring durability during transportation and storage. According to the Freedonia Group, the demand for plastic wrap is projected to reach $9.5 billion by 2025, driven largely by an increase in e-commerce and retail sectors. The food industry, for example, utilizes shrink wrap extensively to extend shelf life for perishable goods, securing them against contaminants.

In addition to food packaging, plastic shrink wrap is widely used in the logistics and manufacturing sectors. It is ideal for bundling products together, reducing packaging costs and improving efficiency in shipping processes. Recent statistics from Smithers Pira indicate that the use of shrink film has grown by 4.8% annually, particularly in the appliance and consumer goods sectors, where protection against scratches and damage is crucial.

Tips: When selecting plastic shrink wrap, consider factors such as thickness, shrink ratio, and clarity. A thicker wrap generally offers better durability, while a higher shrink ratio ensures a tighter fit around products. For businesses prioritizing sustainability, look for eco-friendly shrink wrap options that minimize environmental impact without sacrificing performance.

Plastic shrink wrap is an incredibly versatile material widely used in packaging and storage. One of its significant advantages is its ability to create a tight seal around various items, which helps protect them from dust, moisture, and contaminants. This barrier not only keeps products safe but also extends their shelf life, making it a favorite in various industries including food, retail, and manufacturing. The clarity of shrink wrap also allows for easy identification of the packaged products, adding convenience for both sellers and consumers.

In addition to protection and visibility, plastic shrink wrap offers considerable cost-effectiveness. It requires minimal materials to create a secure package, reducing overall packaging costs without compromising quality. Furthermore, its lightweight nature means that shipping and handling costs can be significantly lowered, making it an economical choice for businesses. Another benefit is the ease of use; shrink wrap can be quickly applied and removed, streamlining the packing process and enhancing efficiency. With its numerous advantages, plastic shrink wrap proves to be an indispensable tool for effective packaging and storage solutions.

| Property | Description | Benefits | Common Uses |

|---|---|---|---|

| Material | Polyethylene or Polyolefin | Durable, resistant to moisture | Industrial and retail packaging |

| Thickness | Ranges from 50 to 200 gauge | Variety for different protection needs | Wrapping items of various sizes |

| Shrink Ratio | Typically 50% shrinkage | Tight fit around products | Securing products for shipment |

| UV Protection | Available in UV-resistant options | Protects contents from sunlight damage | Outdoor storage |

| Temperature Resistance | Suitable for a range of temperatures | Maintains integrity in varying conditions | Food packaging and storage |

When selecting the right type of plastic shrink wrap for your packaging needs, several critical factors must be considered. First, the type of plastic material plays a significant role. Polyolefin and PVC are among the most popular options, each offering unique advantages. According to a report from Smithers Pira, the global demand for shrink film is expected to reach approximately 3.4 million tonnes by 2024, driven in part by the packaging sector's increasing need for efficient and versatile materials. Polyolefin, known for its high clarity and resistance to punctures, is often preferred for food and retail applications, while PVC remains a cost-effective choice for less demanding uses.

Another factor to consider is the thickness of the shrink wrap. The gauge of the film can influence its durability and ability to withstand handling during the shipping process. Research from MarketsandMarkets indicates that thicker films exhibit greater tensile strength and shrink force, which is essential for ensuring products remain secure during transit. Additionally, businesses should evaluate the shrink ratio of the film, as this determines how tightly the wrap conforms to the product when heat is applied. A higher shrink ratio can provide a more precise fit, offering better protection and enhancing aesthetic presentation. Making informed choices based on these factors can lead to improved packaging efficiency and reduced material wastage.

When applying plastic shrink wrap, it’s essential to ensure that the surface you are working on is clean and dry. Any dust or moisture can affect the adhesion of the wrap, leading to suboptimal results. Start by cutting the wrap to the desired size, allowing for enough material to cover the entire item completely. Using a heat gun or a specialized shrink wrap machine can help in achieving the perfect shrink fit. Always keep the heat source moving to avoid burning or melting the plastic in one spot.

For effective use, attention to detail is crucial. Begin at one end of the item and gradually work your way to the other end, making sure to avoid air pockets. If air gets trapped under the wrap, it can lead to uneven shrinkage, compromising the protective barrier. After wrapping, ensure that the edges are securely sealed to prevent moisture and contaminants from getting inside. Finally, store the wrapped items in a suitable environment, avoiding exposure to extreme temperatures or sharp objects that might damage the wrap. Proper application and handling of plastic shrink wrap can significantly enhance its durability and protective capabilities.