Stretch film is an essential tool in the packaging industry. It offers versatility and protection for various products. However, many users struggle with its effective application. Understanding how to use stretch film properly can make a significant difference.

In this article, we provide ten essential tips for using stretch film. These tips are straightforward yet impactful. For instance, ensuring the correct tension while wrapping can prevent damage. Many people overlook proper alignment, leading to wasted materials and time.

Packaging is an art. Not every technique will work for everyone. Reflection on your methods is necessary for improvement. Learning through experience can refine your approach with stretch film. Embracing these tips can lead to better packaging solutions and enhance overall productivity.

Stretch film plays a crucial role in modern packaging solutions. It is more than just plastic wrap. This versatile material securely binds products, preventing damage during transportation. A well-wrapped package reduces the risk of items shifting or breaking. Properly applied stretch film also protects against dust and moisture.

However, many overlook the importance of choosing the right thickness and elasticity. Some film can be too thin, leading to tears. Others may be too thick, wasting resources. Understanding the optimal stretch ratio can ensure efficiency. It’s essential to assess the specific needs of each shipment. Evaluate weight, size, and fragility to select the best type.

Moreover, the application process requires attention to detail. Wrapping techniques can vary based on item shape and weight. A poorly wrapped package is just as detrimental as no wrap at all. Regularly review your methods and implement changes as needed. Analyzing your approach can uncover areas for improvement.

When it comes to selecting the right type of stretch film, understanding product requirements is key. Products can vary greatly in size and shape. A thin film may not provide enough support for heavier items. Conversely, a thick film might be excessive for lighter goods. Assessing the weight and fragility of your products can guide your choice effectively.

Consider the clarity of the film as well. Transparent films allow visibility, which helps with inventory checks. Opaque films, on the other hand, can protect valuable contents from prying eyes. The environment also matters; if items will be exposed to harsh temperatures or chemicals, choosing a specialized stretch film is crucial. Don’t rush this decision; it can impact product integrity.

Lastly, think about the film's stretchability. Some films offer more cling than others. Higher cling can prevent slippage during transport. But, too much cling can make packaging difficult. A balance is essential. It's easy to overlook these details, but being mindful can enhance product protection significantly.

Stretch film is a vital component in the packaging industry. It offers protection and stability for products during transportation. To maximize its effectiveness, focus on proper application techniques.

One critical technique is ensuring tension. Stretch film should be applied with consistent tension to prevent slippage. Insufficient tension can lead to load shifting and damage. Data shows that loads secured with the right tension can minimize transport damage by 40%. This highlights the importance of a careful application.

Another tip involves the use of the right film gauge. Thicker films might seem better, but using a 20-micron gauge saves material and reduces waste. A study found that using a suitable gauge can decrease costs by as much as 15% without compromising load integrity.

The wrapping process itself should not be rushed. Take time to overlap each layer adequately. This creates a tight seal and enhances strength. Sloppy applications leave vulnerabilities. Many companies overlook these details, leading to excess damage and increased expenses. Examine your process regularly and adjust as necessary for better outcomes.

| Tip No. | Tip Description | Key Benefits | Application Techniques |

|---|---|---|---|

| 1 | Choose the right thickness | Enhanced protection for products | Assess product weight and fragility |

| 2 | Utilize appropriate stretch ratio | Optimal load stability | Stretch to 300% for best results |

| 3 | Keep the film clean | Prevents contamination | Regularly inspect and replace rolls |

| 4 | Proper film alignment | Even coverage on all sides | Use guides or templates if necessary |

| 5 | Layer strategic placement | Prevents shifting during transport | Begin securing from the bottom up |

| 6 | Use correct application pressure | Maximizes film performance | Maintain consistent tension |

| 7 | Avoid over-wrapping | Reduces material waste | Wrap only to secure load |

| 8 | Select the right type of stretch film | Customization for specific needs | Consider protective vs. bundling films |

| 9 | Train staff on techniques | Consistency in packaging | Regular training sessions |

| 10 | Inspect finished packages | Quality assurance | Check for looseness and tears |

Using stretch film can greatly enhance your packaging effectiveness, but common mistakes can lead to issues. Many users underestimate the importance of proper tension. According to industry reports, improper tension can lead to load shifting and product damage. A study shows that around 30% of shipped goods are damaged due to inadequate packaging.

One tip is to ensure consistent tension when applying stretch film. This prevents loose ends that can cause product contamination. Additionally, avoid over-wrapping; it wastes film and adds unnecessary weight. Research indicates that optimizing film usage can reduce costs by up to 20%.

Another common mistake is neglecting to choose the right type of film for the job. Not all stretch films are created equal. Some are designed for heavier loads, while others suit lighter items. Failing to match the film to your products can result in disappointing performance.

Finally, always inspect your film before use. Look for tears or defects that could compromise your packaging. Paying attention to these details can significantly impact your overall efficiency and reduce the chance of errors. By avoiding these pitfalls, you’ll achieve better outcomes in your packaging solutions.

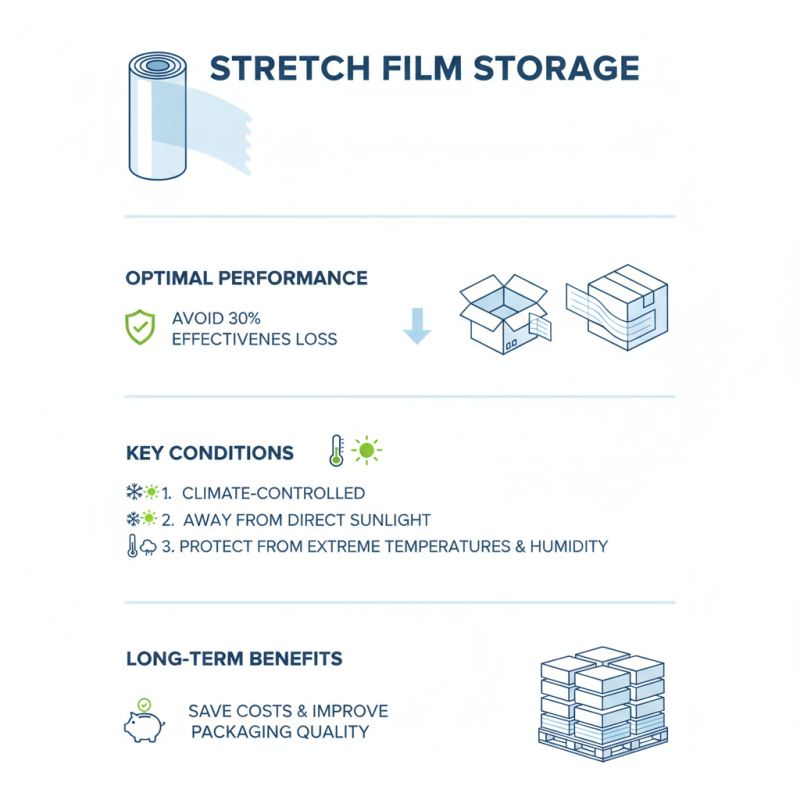

Proper storage and handling of stretch film is crucial for ensuring optimal performance. According to industry reports, improperly stored stretch film can lose its effectiveness by up to 30%. This loss can significantly impact packaging quality. Stretch film should be kept in a climate-controlled environment, away from direct sunlight and extreme temperatures. High humidity can also affect its stretchability. Ensuring your film is stored properly can save costs in the long run.

When handling stretch film, attention to detail is essential. Always check for punctures or tears before use. A small defect can lead to packaging failures. In a recent study, it was noted that 15% of all packaging issues stem from inadequate film quality due to mishandling. Additionally, using the right equipment for wrapping can improve consistency. Manual wrapping may lead to uneven tension, causing film breakage and wasted material. Rethinking your handling practices can enhance packaging efficiency greatly.