Cross-Linked Shrink Film has become an essential material in various industries. John Smith, a leading expert in packaging technology, states, "Cross-Linked Shrink Film is revolutionizing how we package products." This versatile film offers enhanced durability and performance compared to traditional shrink films.

The properties of Cross-Linked Shrink Film make it ideal for demanding applications. Its ability to withstand high temperatures and resist tearing is impressive. Many manufacturers turn to this film for packaging their products securely. It ensures that items arrive at their destination intact and safe.

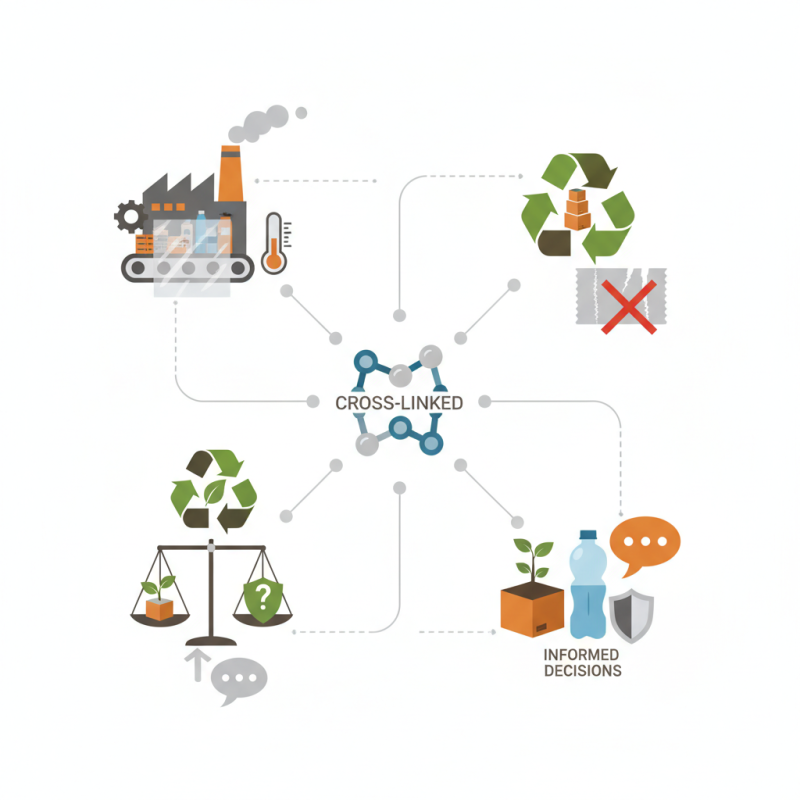

However, not all consumers are aware of its benefits. Some may question its environmental impact. While it provides strength and protection, the long-term consequences of plastic use must be considered. It's a balancing act between performance and sustainability. The ongoing dialogue about packaging materials is crucial in today’s eco-conscious world. Understanding Cross-Linked Shrink Film's role is a step towards making informed decisions.

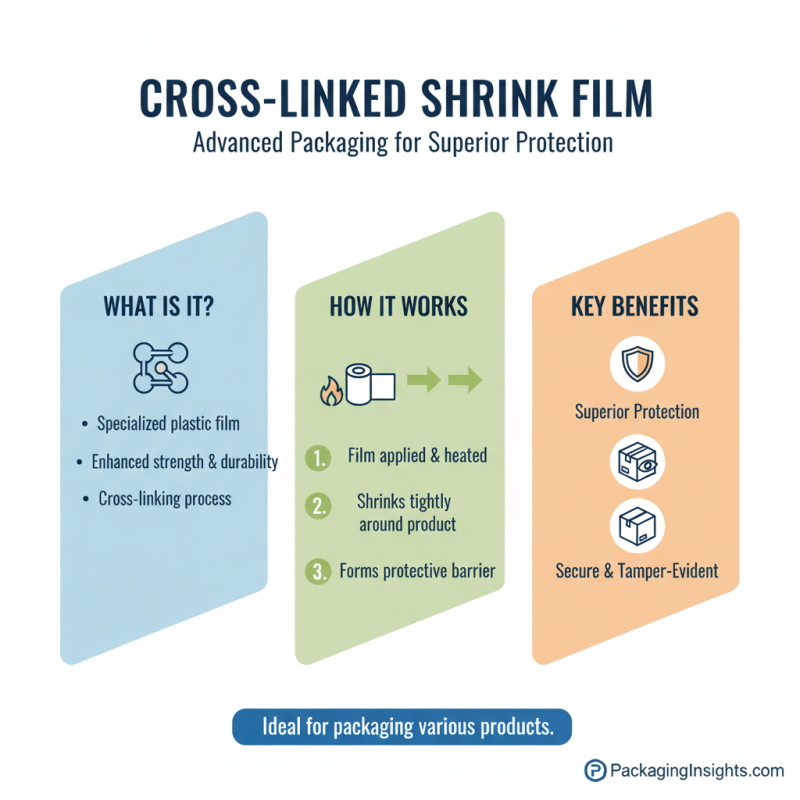

Cross-linked shrink film is a specialized type of plastic film. It undergoes a process that enhances its strength and durability. This makes it ideal for packaging various products. When heated, this film shrinks tightly around the item it encases. This snug fit provides excellent protection. It also ensures that the product remains visible.

Manufacturers often use cross-linked shrink film for packaging. Its versatility makes it suitable for different industries. Food, electronics, and retail all benefit from this type of packaging. It enhances shelf life and prevents damage during transport. However, not every application is perfect with this film. Improper sealing can lead to issues like leaks. It is crucial to test and adjust the settings for optimal results.

While the benefits are clear, challenges remain. Shrink film can be sensitive to temperature. Excessive heat may compromise its structural integrity. Users must be careful during the shrink-wrapping process. Mistakes can lead to wasted materials and time. Thus, understanding the film's properties is essential for effective use.

Cross-linked shrink film is a versatile packaging solution. Its unique properties make it suitable for various applications. One of the key properties is its enhanced strength. This film can withstand stress without tearing easily. It offers better resistance to punctures, which is essential for protecting products during shipping.

Another important feature is its temperature tolerance. Cross-linked shrink film performs well in extreme temperatures. It can shrink uniformly when heated, covering products tightly. This property helps secure items without leaving extra space. In addition, the film is often resistant to chemicals. It means it can protect contents from exposure to harmful substances.

However, using cross-linked shrink film requires careful planning. Sometimes, improper heat settings can lead to uneven shrinking. This can jeopardize the film's protective qualities. It’s crucial to test different settings. Achieving the right balance ensures efficiency and quality. Users must remain vigilant about production details for optimal results.

Cross-linked shrink film has become an essential material in the packaging industry. It offers superior strength and durability compared to traditional shrink films. This makes it particularly valuable for industries that require high-performance packaging solutions.

One of the primary applications of cross-linked shrink film is in food packaging. According to a report by Grand View Research, the global shrink film market is projected to reach approximately $12 billion by 2025. This growth is driven by the demand for safe and efficient packaging. Cross-linked films help maintain freshness and extend shelf life. They are resistant to punctures and tears, which is crucial for perishable goods.

In the beverage sector, cross-linked shrink films are often used for bundling products. They provide stability and protection during transport and storage. A study by Research and Markets indicated that the beverage industry's packaging needs are evolving. As sustainability becomes important, cross-linked films can be designed to reduce waste while improving performance. However, this shift also presents challenges. Manufacturers must balance functionality with environmental concerns, leading to complex decision-making in material sourcing and production strategies.

Cross-linked shrink film has become increasingly popular in various packaging applications. One of its main advantages is its superior strength compared to conventional films. This strength ensures that products are securely wrapped and protected from damage during transport. The cross-linking process enhances the material's durability, which means it can handle varying temperatures and conditions better than standard shrink films.

Another significant benefit is the improved clarity and gloss of cross-linked films. This quality not only enhances the product's appearance but also allows for better visibility of the packaged items. Customers are often drawn to clear packaging, as it provides a glimpse of the product inside. Additionally, cross-linked films are less prone to tearing, reducing waste and, ultimately, costs.

However, it’s essential to reflect on the environmental implications of using these materials. While they offer excellent performance, they are not always biodegradable. This raises questions about sustainability in packaging. It may be tempting to prioritize performance over environmental impact, but finding a balance is crucial for responsible packaging practices.

The market for cross-linked shrink film is evolving rapidly. Manufacturers are focused on improving product performance and sustainability. Enhanced protection for products during shipping is a key driver. Soft-touch materials and improved clarity are highly sought after by packaging designers. However, the industry faces challenges in sourcing raw materials effectively.

End users are increasingly demanding environmentally friendly options. The shift towards circular economies influences purchasing decisions. Biodegradable variants are gaining traction. Yet, many still rely on traditional films, hesitant to change. Cost is a concern for many businesses. The balance between sustainability and expense remains an ongoing debate.

Innovation is crucial for future growth. Emerging technologies may lead to better film properties. Research into new polymers could yield exciting results. Some companies struggle to adopt these advancements. They fear investing in new technology may not pay off. Collaboration between manufacturers and clients will be essential. Despite uncertainties, the future for cross-linked shrink film appears promising.

This bar chart illustrates the growth trajectory of the cross linked shrink film market from 2019 to 2023, indicating a steady increase in market value, driven by rising demand in packaging and industrial applications.