When it comes to packaging, selecting the right materials is essential. Stretch Film is a popular choice for many businesses. However, not all Stretch Films are created equal. Understanding the differences can greatly impact your efficiency and costs.

Choosing the best Stretch Film requires careful consideration. Factors like thickness, stretchability, and clarity can influence your decision. A clearer film allows for easy scanning and visibility. Thicker films often provide better protection but may come at a higher price.

There is also the aspect of environmental impact. Some Stretch Films are recyclable, while others may not be. It’s worth reflecting on the long-term implications of your choices. Packaging should protect your products without harming the planet. Explore your options wisely, as your choice can make a significant difference.

Stretch film plays a crucial role in packaging and logistics. It’s essential to understand its types and applications. Stretch film is typically made from linear low-density polyethylene (LLDPE). It comes in various thicknesses, which impacts its strength and performance. According to industry reports, the demand for stretch film is expected to grow by 5% annually through 2026. This growth reflects the increasing need for efficient shipping processes.

When choosing stretch film, consider how it will be used. For palletizing, a thicker film provides better load stability. Films with high puncture resistance are beneficial for handling sharp edges. A study by the Packaging Association noted that improper film selection can lead to damaged products and increased costs. This highlights the need for careful evaluation of film properties against specific requirements.

It’s important to recognize that not all stretch films are created equal. Some may not perform well in extreme temperatures, affecting product integrity. Additionally, the choice of film can impact recycling efforts. Reports indicate that about 30% of businesses face challenges due to film wastage. Reflecting on these factors can aid companies in making more informed decisions, ultimately improving their packaging efficacy.

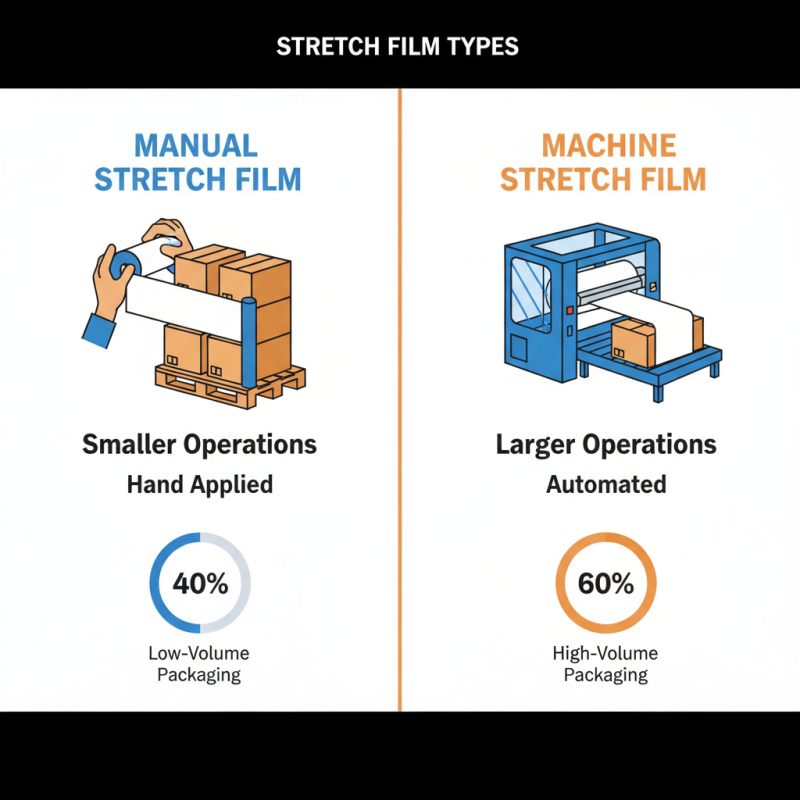

When choosing stretch film for packaging, consider two main types: manual and machine stretch films. Manual stretch films are often utilized in smaller operations. They are applied by hand, making them versatile but labor-intensive. According to industry reports, nearly 40% of companies prefer manual methods for low-volume packaging tasks.

On the other hand, machine stretch films are designed for automated processes. They are ideal for large-scale operations. Research indicates that machine stretch films can increase efficiency by over 30% compared to manual methods. The automated wrapping process reduces labor costs and minimizes the risk of packaging errors. However, transitioning to machine films requires investment in machinery and training, which some businesses may hesitate to undertake.

Both types come with unique challenges. Manual films may result in inconsistent application, leading to potential damage during transit. Machine films, while efficient, can sometimes be overly sensitive to stretch settings. This sensitivity can cause waste if not monitored properly. Evaluating these factors is crucial for optimal packaging solutions.

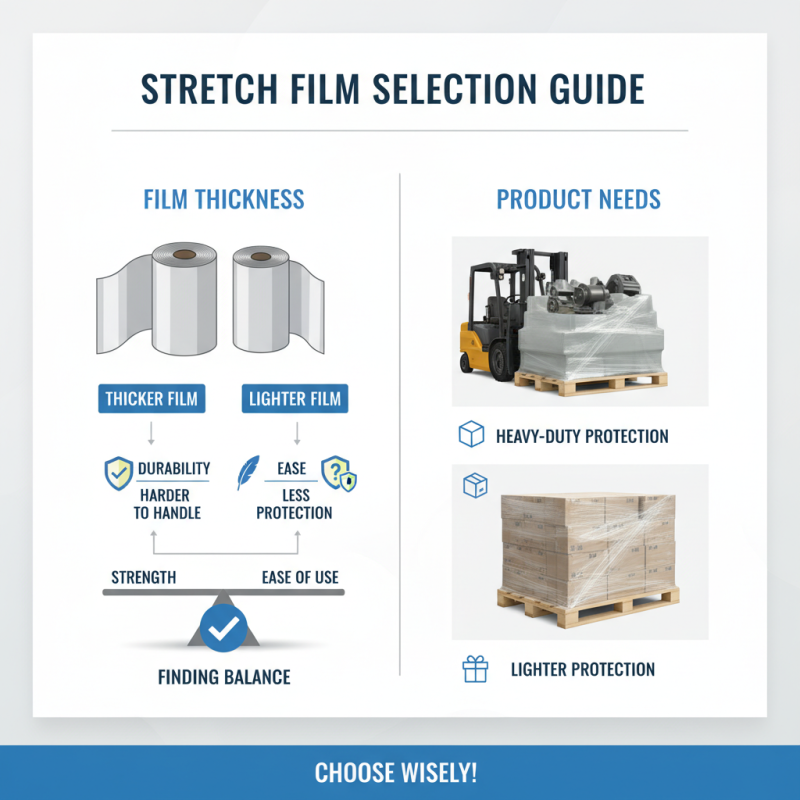

When selecting stretch film for packaging, several key factors come into play. The first is the thickness of the film. Thicker films provide better puncture resistance and durability. However, they can be more challenging to handle. A balance between strength and ease of use is crucial. Consider what your specific needs are. Will the products require heavy-duty protection, or is lighter film sufficient?

Another important aspect is the clarity of the film. High clarity allows for visibility of the products. This can enhance branding and customer experience. Conversely, reduced clarity may save on costs but can lead to a less appealing presentation. Think about what is more critical for your packaging strategy.

Stretch film stretchability is another factor worth mentioning. Some films stretch more than others. A higher stretch rate can lead to better load containment. However, a film that stretches too much may compromise stability. Testing different options is essential. Understand how each choice fits into your overall packaging process. Each factor is intertwined and can significantly affect your operations and results.

When selecting stretch film, understanding its performance and strength is essential. Various factors influence these qualities. The thickness of the film plays a crucial role. Thicker films generally offer better strength. However, they can also be more challenging to handle and require more storage space. Balancing between thickness and practicality is vital.

Stretch film also comes in different types. Cast and blown films are the two main varieties. Cast film is often clearer and offers good stretchability. Blown film, on the other hand, is thicker and can provide greater strength. Each type has its benefits and drawbacks, creating a complex decision process. While it’s tempting to opt for the strongest option available, it may not always be necessary. It’s wise to reflect on the specific requirements of your packaging scenario.

Strength testing is another important aspect. Conducting real-world tests can reveal weaknesses in the film. Not all films perform as advertised, leading to potential issues during transportation. Remember, a successful choice should also consider cost and usability. Sometimes, the most expensive option isn't the best for your needs. Taking time to evaluate various films will lead to better outcomes and fewer regrets in the long run.

When selecting stretch film for packaging, environmental impact plays a crucial role. Many films are made from plastic, creating waste that lingers for years. Eco-friendly options exist, but they may not always perform the same as traditional films. It is essential to weigh these differences carefully.

Biodegradable stretch films offer a greener alternative. However, they may have limitations in strength and durability. Testing different types can help determine the right balance between performance and sustainability. Some businesses opt for recyclable films. This choice encourages a circular economy but may not be a complete solution.

It's crucial to implement proper disposal strategies. Simply using eco-friendly film is not enough. Educating staff on recycling practices is vital. Mistakes can happen, leading to materials ending up in landfills. Continuous reassessment of packaging practices is necessary. As technology evolves, so do potential solutions for reducing environmental harm.