When selecting a shrink packing machine for your business, understanding the specific needs of your operations is crucial. Industry expert John Peterson, a consultant with over 15 years of experience in packaging machinery, emphasizes the importance of this process by stating, "Choosing the right shrink packing machine is not just about the equipment itself, but how well it aligns with your production goals." This insight highlights that while the technical specifications of a shrink packing machine are essential, aligning those specifications with your business requirements can significantly impact efficiency and profitability.

Shrink packing machines come in various designs and functionalities, each tailored for different packaging needs. Whether you are looking to enhance product protection, extend shelf life, or improve aesthetic appeal, the right machine can make a difference. The decision-making process involves evaluating factors such as production volume, product dimensions, and the types of materials you will be packing. By understanding these elements, businesses can make informed choices that not only optimize their packaging processes but also contribute to overall operational success.

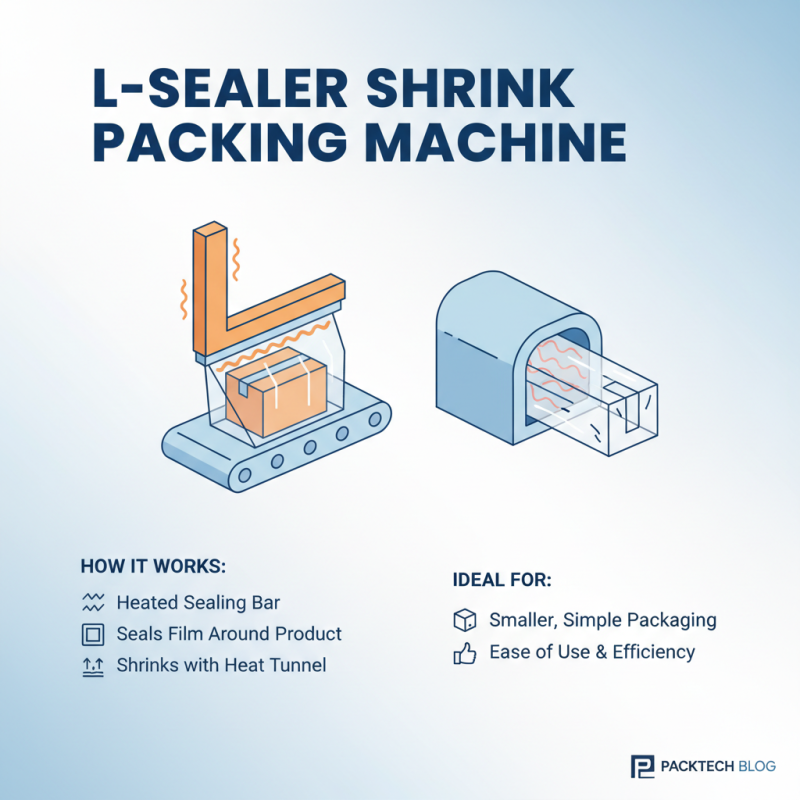

When selecting the right shrink packing machine for business requirements, it’s crucial to understand the various types available in the market. One common type is the L-sealer, which utilizes a heated sealing bar to create a perfect package by sealing the film around the product and then shrinking it with the help of a heat tunnel. This method is particularly effective for smaller, less complex packaging needs and is favored for its ease of use and efficiency.

Another key type is the chamber shrink packaging machine. This machine is ideal for businesses with high-volume production needs. Chamber machines allow for complete control over the shrink process, as products are placed inside a chamber where a heat source envelops them. This provides an even shrink and is suitable for a variety of product shapes and sizes, ensuring that even delicate items are securely packaged without damage. Understanding these types can help businesses determine which machine will optimize their packaging process while meeting their specific production demands.

Choosing the right shrink packing machine involves several key factors that are vital for aligning the equipment with your business needs. First and foremost, consider the volume of products you need to package. A high-speed machine may be necessary for businesses with large output, while smaller operations might benefit from a compact, less expensive model. Assessing your production scale will help determine whether you need a fully automated system or a semi-automatic one, saving time and labor costs without compromising efficiency.

Another crucial factor to consider is the size and type of products being packed. Different machines feature varying shrink profiles, suitable for different shapes and sizes. It's important to select a machine that can accommodate your products effectively to ensure efficient shrink wrapping without damage. Additionally, consider the types of materials you will be using; the machine should be compatible with the shrink films required for your specific packing needs. Ultimately, taking into account your production volume and product specifications will aid in making an informed decision that enhances your operational workflow.

When selecting the right shrink packing machine for your business, evaluating production capacity and efficiency is paramount. Industry reports indicate that the global shrink packaging market is projected to reach USD 78 billion by 2026, highlighting the increasing reliance on effective packaging solutions across various sectors. A machine's production capacity directly influences operational efficiency and cost-effectiveness, with typical output rates ranging from 20 to 300 packages per minute depending on machine type and application.

To maximize efficiency, businesses should first analyze their packaging needs—understanding the volume of products and the speed required for packaging can help in choosing a machine that aligns with these specifications. For example, a mid-sized business might benefit from a machine that offers adjustable speed settings, allowing for flexibility in production as demand fluctuates. According to a study by Packaging Machinery Manufacturers Institute, streamlined packing processes can cut labor costs by 20-30%, underscoring the financial benefits of selecting the right equipment.

Tips: When assessing different machines, consider their compatibility with your current production line and the types of products you handle. Machines that offer quick changeover capabilities and easy maintenance can significantly enhance operational uptime. Additionally, explore options that provide energy-efficient operations, as sustainability initiatives are becoming crucial for modern businesses and can lead to long-term cost savings.

When evaluating cost-effectiveness and return on investment (ROI) in shrink packaging, businesses must consider several critical factors. Initially, it's essential to calculate the total costs associated with the shrink packing machine, including purchase price, maintenance, and operational expenses. While a lower initial purchase price may seem attractive, it is crucial to assess whether the machine can handle production demands efficiently and consistently, which can ultimately affect profitability.

Additionally, understanding the potential for increased productivity and reduced labor costs is vital when analyzing ROI. A high-quality shrink packing machine can significantly streamline packaging processes, leading to faster turnaround times and less manual labor. By minimizing downtime due to machine failures and maximizing throughput, businesses can improve their overall operational efficiency, directly impacting their bottom line. Ultimately, a careful balance of upfront costs against potential long-term gains will guide businesses in selecting the most suitable shrink packing solution for their needs.

When selecting a shrink packing machine, it's essential to consider the specific requirements of your industry to ensure optimal performance and efficiency. Different sectors, such as food and beverage, pharmaceuticals, or consumer goods, often have unique packaging guidelines that dictate machine capabilities. For instance, the food industry typically demands equipment that meets stringent hygiene and safety standards, requiring machines that provide easy cleaning and maintenance features. Understanding these requirements is crucial for aligning your machine choice with quality control measures vital for compliance and customer satisfaction.

Additionally, the volume and type of products being packaged play a significant role in machine selection. Industries that deal with high throughput will benefit from machines designed for speed and automation, reducing bottlenecking in production lines. In contrast, companies focusing on small batches or customized packaging might need machines equipped for versatility and quick changeovers. Assessing your production rate, product dimensions, and the nature of the materials will provide clarity on the specifications that your shrink packing machine must meet, ensuring it supports your operational goals effectively.