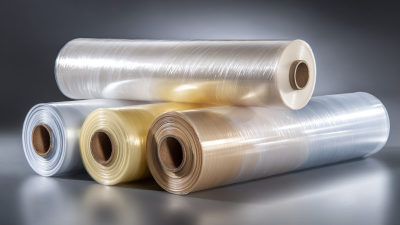

When it comes to packaging, selecting the right materials is crucial for ensuring product protection and enhancing visual appeal. One of the most versatile and effective options available on the market is the Shrink Film Roll. This dynamic packaging solution not only provides a secure barrier against dust and moisture but also allows for a professional presentation of your products. As we move towards 2025, understanding the various types of shrink films can help businesses and individuals alike make informed decisions tailored to their specific packaging needs.

In this guide, we will explore the essential factors to consider when choosing the best Shrink Film Roll. From assessing the dimensions and specifications of your products to understanding the different materials and their properties, each aspect plays a vital role in achieving optimal packaging results. Furthermore, we will provide practical tips to navigate the selection process, ensuring that you choose a shrink film that meets not only functionality but also budgetary requirements. By considering these elements, you can enhance your packaging strategy and ensure the effective delivery of your products to customers.

When selecting the best shrink film roll for your packaging needs, several key factors should be considered to ensure optimal performance in various applications. First and foremost, the type of product being packaged plays a critical role in the choice of shrink film. For instance, food items often require films with food-safe certifications and properties that enhance shelf life, while non-food items might prioritize durability and puncture resistance. Additionally, the size and shape of the products dictate the film's gauge and width, which must accommodate the specific dimensions to provide a snug and protective wrap.

Another important factor is the shrink temperature of the film. Different applications may demand varying levels of heat to achieve the desired shrink ratio, which influences the efficiency of the packaging process. For temperature-sensitive products, a film with a lower shrink temperature can prevent damage. Furthermore, understanding the environment in which the packaged goods will be stored or displayed is critical; for example, films that are resistant to moisture and UV light may be necessary for outdoor or refrigerated applications. Considering these elements will help ensure that you choose the most suitable shrink film roll tailored to your specific packaging objectives.

When selecting the best shrink film roll for your packaging needs, it’s essential to understand the various types of shrink films available in the market. There are primarily three categories: PVC (Polyvinyl Chloride), Polyolefin, and PLA (Polylactic Acid). Each type offers distinct properties that cater to different packaging requirements. PVC is a popular choice for its excellent clarity and shrink capabilities, making it suitable for retail packaging where presentation is key. However, it may not be the best option for heat-sensitive products due to its lower heat resistance.

On the other hand, Polyolefin is known for its versatility and strength, making it ideal for a range of applications, from food packaging to industrial uses. It provides a high-quality seal and is more resistant to punctures and tears, which is crucial for transporting goods. Lastly, PLA is an eco-friendly alternative that appeals to brands focusing on sustainability. Made from renewable resources, PLA shrink film is biodegradable and suitable for environmentally conscious packaging solutions. Choosing the right type of shrink film roll depends on your specific needs, including product type, budget, and environmental considerations.

| Type of Shrink Film | Material | Thickness (Microns) | Common Applications | Shrink Ratio | Temperature Range (°F) |

|---|---|---|---|---|---|

| PVC Shrink Film | Polyvinyl Chloride | 50 - 100 | Product Bundling, Displays | 2:1 | 300 - 400 |

| PE Shrink Film | Polyethylene | 30 - 75 | Food Packaging, Pallet Wrapping | 3:1 | 250 - 400 |

| PP Shrink Film | Polypropylene | 20 - 60 | Bottles, Gifts | 2:1 | 275 - 425 |

| PLA Shrink Film | Polylactic Acid | 40 - 80 | Eco-Friendly Packaging, Food Packaging | 2:1 | 240 - 380 |

| Cross-Linked Shrink Film | Polyolefin | 25 - 85 | Heavy-Duty Packaging, Electronics | 2:1 | 300 - 450 |

As the global shrink film market is projected to grow significantly by 2025, understanding industry trends becomes essential for businesses seeking effective packaging solutions. The worldwide shrink packaging market is estimated to reach $12.27 billion in 2025, driven by a growing demand for efficient and sustainable packaging options. This growth highlights a shift towards eco-friendly materials, responding to consumers' increasing preference for biodegradable packaging solutions. As sustainability takes precedence, manufacturers are exploring innovative materials and technologies to cater to this emerging demand.

In parallel, the vacuum packaging market is also expected to see substantial growth, estimated to be valued at $32.91 billion by 2025. The rise in the usage of automatic shrink packaging machines, projected to reach $1.44 billion, indicates an industry trend towards automation and efficiency. Companies are increasingly investing in advanced packaging machinery that not only enhances productivity but also reduces waste. As these trends evolve, businesses must carefully consider the type of shrink film that aligns with their packaging needs, balancing performance, environmental impact, and cost-effectiveness to stay competitive in the ever-changing market landscape.

This chart demonstrates the projected usage of different shrink film materials by percentage in the packaging industry for 2025. The data suggests that PVC remains the most widely used material, followed by PE and PP, with newer materials like PLA seeing an incremental increase in adoption.

Selecting the right shrink film roll for packaging demands careful consideration of several key performance indicators (KPIs) that define film quality and suitability. One of the primary KPIs is the material's shrinkage percentage. According to a report by Smithers Pira, optimal shrink rates typically range from 40% to 60%, with variations depending on product shape and design. This metric directly influences the tightness of the film around the product, impacting both protection and presentation.

Another crucial factor is puncture resistance, which ensures the integrity of the packaging during handling and transport. Industry standards indicate that films with a puncture resistance of over 30 grams per mil significantly outperform those below this threshold, leading to fewer damages and product losses. Additionally, clarity is vital for visual appeal. High-quality shrink films often boast clarity ratings of 90% or more, enhancing product visibility while preventing distortion. In a competitive marketplace, brands prioritizing these KPIs not only improve their packaging effectiveness but also enhance consumer trust and product appeal.

When choosing shrink films for packaging, environmental considerations have become increasingly important. Sustainable shrink films are designed to minimize environmental impact while still providing the protective qualities required for product packaging. These eco-friendly options often utilize materials such as bio-based plastics or are made from recycled content. By opting for such films, businesses not only reduce their carbon footprint but also align their practices with the growing consumer demand for sustainable products.

Another critical factor to consider is the recyclability of shrink films. Many manufacturers are now producing films that are easily recyclable, enabling a circular economy approach. Packaging made from these materials can be collected, processed, and reused, further diminishing waste. Additionally, advancements in technology have led to the development of films that can biodegrade under specific conditions, offering a viable solution for businesses aiming to enhance their sustainability efforts. By prioritizing these environmentally friendly aspects, companies can contribute to a healthier planet while still ensuring their products are effectively packaged.