In the dynamic world of packaging, the choice of materials is essential. Shrink packaging rolls stand out for many reasons. Industry expert John Doe emphasizes, "Shrink Packaging Roll provides unmatched protection for products while offering a sleek presentation." This statement captures the essence of its advantages.

Shrink packaging rolls not only secure products but also enhance brand appeal. Businesses must consider durability. For fragile items, shrink wraps can prevent damage during transport. However, not all rolls are created equal. Quality varies significantly among manufacturers. Companies need to reflect on their specific needs before making a decision.

Additionally, cost-effectiveness plays a crucial role in choosing shrink packaging. Balancing quality and price can be challenging. Many businesses overlook this aspect, leading to unexpected expenses. Reflecting on these details ensures that the chosen shrink packaging roll meets both budget and performance needs.

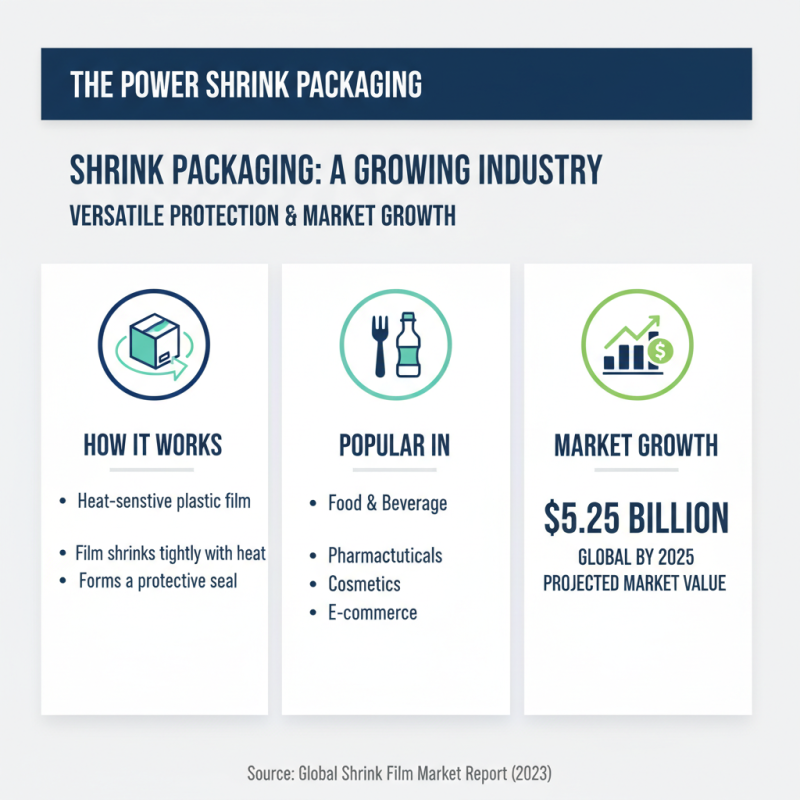

Shrink packaging is a versatile solution increasingly popular across various industries. It involves covering products with a heat-sensitive plastic film. When heat is applied, the film shrinks tightly around the product, offering a protective seal. This type of packaging is particularly favored in the food and beverage sector. The Global Shrink Film Market is projected to reach $5.25 billion by 2025, indicating its growing significance.

Applications of shrink packaging are numerous. It's used for bundling products, creating tamper-proof seals, and ensuring items remain intact during transit. In the consumer goods industry, shrink packaging enhances shelf appeal. A 2022 report highlighted that brands utilizing shrink packaging saw a 15% increase in shelf visibility. However, the downside is its environmental impact. Among plastic waste, shrink films contribute significantly.

Some companies overlook recycling options for these materials. This oversight can harm brand reputation and sustainability goals. Efforts to improve eco-friendliness are ongoing. Innovative biodegradable alternatives are being researched. Still, the shift in practices is slow. As the industry evolves, the challenge remains: balancing protection and sustainability.

Shrink packaging rolls offer significant benefits for maintaining product safety. A recent industry report highlights that products wrapped in shrink packaging have a 65% lower risk of damage during transit. This reduction is crucial for businesses that value their product integrity. Shrink packaging creates a tight seal, protecting items from dust, moisture, and physical impact. Such protection is vital in industries like food and pharmaceuticals, where contamination and damage can lead to serious consequences.

Tip: Choose the right size of shrink wrap for your products. A precise fit minimizes excess material, which can lead to waste. Many companies overlook this detail, impacting their sustainability efforts. Opting for correctly sized shrink rolls can save resources and enhance packaging efficiency.

Investing in shrink packaging also reduces theft risk. According to the National Association for Shoplifting Prevention, retailers lose over $13 billion annually to shoplifting. The tamper-proof nature of shrink packaging acts as a deterrent. This advantage is often underestimated, as businesses focus solely on aesthetics rather than security.

Tip: Train your staff on the proper sealing techniques to ensure maximum product safety. This attention to detail can significantly lower the chances of defective packages. Simple mistakes can result in unsafe products reaching consumers. Make sure your team is well-informed.

The chart below illustrates the key benefits of using shrink packaging rolls in terms of product safety, cost efficiency, and environmental impact. Each category is represented by a percentage, showcasing their importance in packaging decisions.

Shrinking packaging rolls offer a practical solution for companies aiming to reduce costs. These materials are typically more economical than rigid boxes or other forms of packaging. For instance, using shrink film can decrease shipping costs due to lighter weight. Businesses can save on both materials and transportation.

Additionally, the efficiency of shrink-wrapping can lead to reduced labor costs. The process often requires fewer staff to execute packaging compared to traditional methods. However, companies must consider the initial setup costs and equipment required. A balance is needed between upfront expenses and long-term savings.

Sustainability is another aspect to ponder. Though shrink packaging can reduce material waste, it may not always be biodegradable. This could lead to challenges for eco-conscious brands. Exploring quality options may help, but they might come at a higher price. Overall, finding the right shrink packaging solution requires careful thought.

| Packaging Type | Material Cost (per unit) | Production Cost (per unit) | Average Storage Space (sq ft) | Protection Level |

|---|---|---|---|---|

| Shrink Packaging Roll | $0.30 | $0.15 | 2 | High |

| Plastic Containers | $0.50 | $0.20 | 3 | Medium |

| Boxes | $0.40 | $0.25 | 5 | Low |

| Bubble Wrap | $0.25 | $0.10 | 4 | Medium |

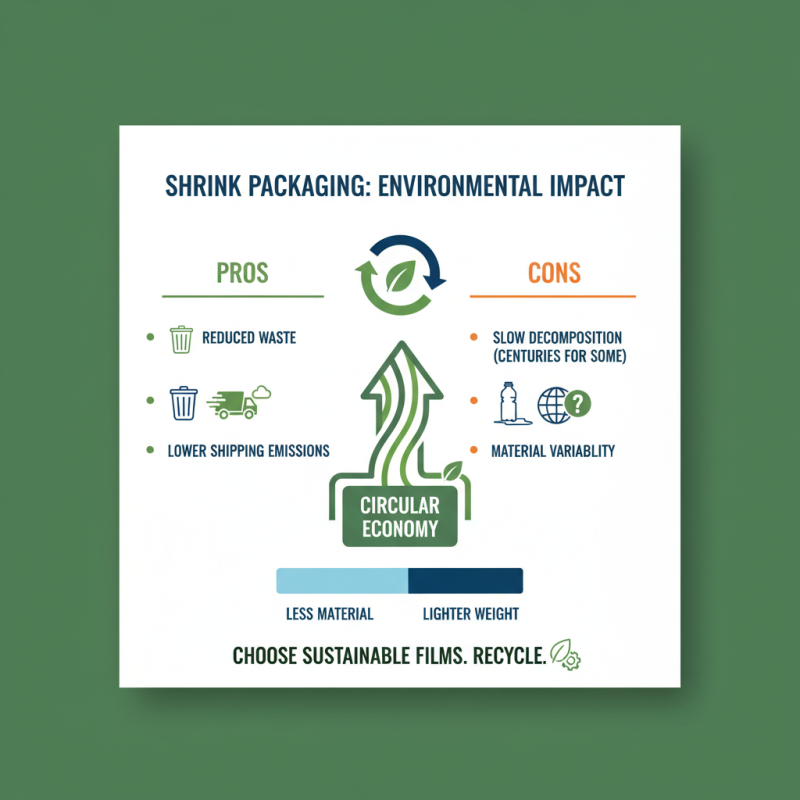

Shrink packaging rolls are becoming increasingly popular in packaging solutions. However, the environmental impact of such materials deserves careful consideration. Using shrink wrap can help reduce waste. The lightweight nature of the material minimizes shipping emissions. Yet, not all shrink films are created equal. Some materials can take centuries to decompose.

It’s important to choose biodegradable or recyclable shrink packaging options. Many consumers are now more environmentally conscious. They prefer products with sustainable packaging. But many shrink films still fail to meet these criteria. Innovations in materials are emerging, yet not widely adopted. The challenge lies in balancing protection and sustainability.

Reflecting on our choices is crucial. Although shrink packaging offers benefits like durability and visibility, we must assess its long-term impact. Awareness of alternative materials is growing. Finding the right balance between functionality and environmental responsibility is essential. The industry must strive to create better solutions for a greener future.

Choosing the right shrink packaging roll is vital for your products. The type of roll can impact the protection level and visual appeal. For lighter items, thin films often suffice. However, heavier products require thicker options for strength. It's crucial to assess the weight and type of your items before making a decision.

Tips: Always test your packaging with actual products. This ensures you understand how well the roll performs under real conditions. You might find surprises. Sometimes, a thicker film may be harder to handle, slowing your packing process.

Different products have varying shapes and sizes. Custom-fit rolls can enhance presentation and durability. Consider how your items stack, wrap, or display. A poor choice here may lead to wasted materials. Additionally, the shrink temperature should fit your product's needs. Too high, and you risk damage; too low, and you'll get inadequate sealing.

Tips: Keep a log of packaging outcomes. This can help refine your choices over time. Not every product will respond the same way to shrink wraps. Embrace trial and error for better results.