Choosing the right Shrink Wrap Packaging can significantly influence your product’s success. According to John Smith, a leading expert in packaging solutions, “The right wrap can protect products and enhance shelf appeal.” His insight emphasizes the connection between packaging quality and overall consumer satisfaction.

Shrink Wrap Packaging is versatile and suitable for various products. It provides a tight seal that protects items from dust, moisture, and tampering. However, not all shrink wraps are created equal. Factors like material type, thickness, and clarity can greatly impact your choice. Choosing poorly can lead to damaged goods or increased costs.

Many businesses overlook these details. They may choose a cost-effective option and later regret it. Inadequate packaging can result in returns and unhappy customers. It’s essential to evaluate the specific needs of your products before making a decision. Reflecting on the features and benefits of each shrink wrap option can lead to better choices and improved packaging performance.

Shrink wrap packaging is essential for many products, providing protection and preservation. Understanding the various types and materials available can significantly impact your packaging decision. Polyolefin and PVC shrink films are among the most commonly used. According to industry reports, polyolefin films account for 70% of the shrink wrap market due to their superior clarity and resistance to temperature changes.

When selecting shrink wrap materials, consider the characteristics of each type. Polyolefin is generally more versatile, suitable for both food and non-food items. On the other hand, PVC shrink wraps are often cheaper but may not perform as well under varying conditions. Research indicates that about 30% of companies encounter issues with product spoilage due to inadequate packaging. This highlights the importance of making informed decisions on material choice.

Environmental sustainability is another factor to consider. Some shrink films are recyclable, while others are not. A study found that 49% of consumers prefer products with sustainable packaging. This emphasizes a potential gap in the market. Choosing the right material not only affects product safety but can also influence customer perceptions. Balancing cost, effectiveness, and eco-friendliness can be challenging, yet it is a crucial reflection point for businesses aiming to enhance their packaging strategy.

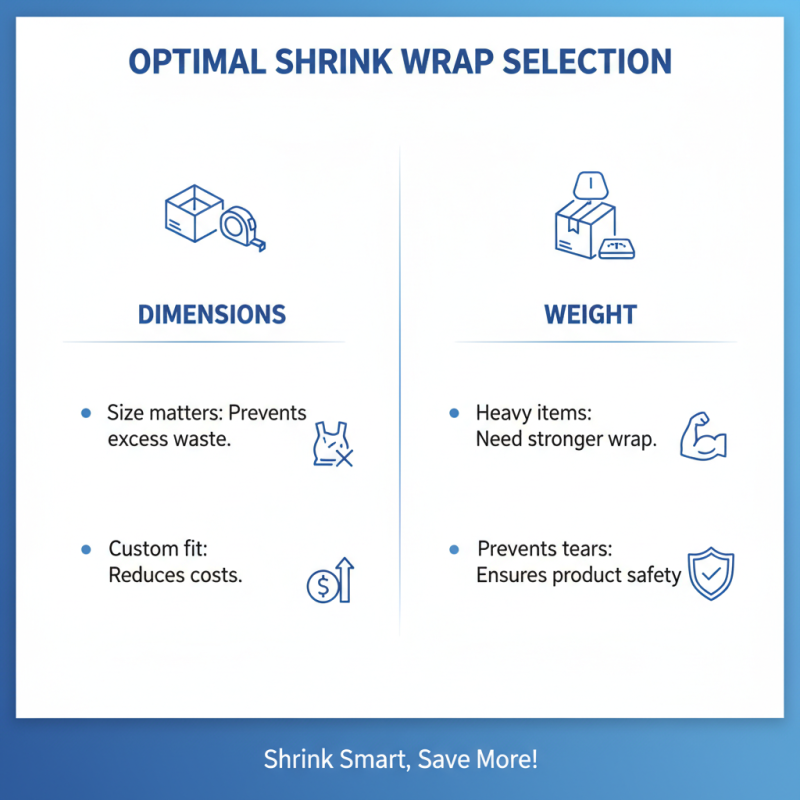

When choosing shrink wrap for your products, consider dimensions and weight carefully. The size of your items dictates the shrink wrap type you need. A standard measurement can lead to extra waste. This can be frustrating and increase costs. Weight is equally critical. Heavy items require stronger shrink wrap to prevent tears.

Take a moment to measure your products accurately. Not every package fits perfectly into the same category. You might find that a slightly larger wrap reduces efficiency. Sometimes, it feels tempting to choose a one-size-fits-all option. However, the results can be unsatisfactory. Inspect how the wrap conforms to various shapes. Look for gaps or uneven edges; these imperfections can compromise protection.

Reevaluate your choices over time. What worked for one product might fail for another. Be open to feedback about your packaging. Efficiency ratings can change as your product line expands. Keep experimenting with different materials. Find the right balance between protection and cost. In the long run, attention to detail can yield better results.

When choosing shrink wrap, consider the environmental impact of your materials. Traditional plastic films can take years to decompose, contributing to pollution. Alternatives such as biodegradable or recyclable shrink wraps are available. These options reduce waste and are better for the planet.

Tips for sustainable shrink wrap choices: Look for materials labeled as compostable. Check their certifications before purchasing. A small change in your packaging can have a big impact. Also, think about sourcing. Production methods matter. Local materials often have a smaller carbon footprint.

It's important to recognize that not all shrink wraps are created equal. Some may appear eco-friendly but still contain harmful additives. This can be misleading. Always scrutinize product labels and manufacturer claims. Environmental friendliness should be a priority, not an afterthought.

| Shrink Wrap Type | Material Used | Recyclability | Environmental Impact | Recommended Products |

|---|---|---|---|---|

| Polyethylene (PE) | Low-Density Polyethylene | Yes | Lower carbon footprint, widely recyclable | Food packaging, merchandise |

| Polyvinyl Chloride (PVC) | Polyvinyl Chloride | Limited | Higher environmental concerns, difficult to recycle | Non-food items, electronics |

| Polyolefin | Polypropylene or polyethylene blend | Yes | Lower toxicity, recyclable options available | Snack foods, retail products |

| Biodegradable Shrink Wrap | Plant-based materials | Yes | Highly sustainable, minimal environmental impact | Organic products, eco-friendly brands |

Choosing the right sealing method for shrink wrap can be challenging. It depends on your product's size, shape, and material. For small items, a manual heat gun might suffice. Larger products often require a more robust system. Think about efficiency; a well-chosen machine can save time and labor.

Different sealing techniques exist, such as band sealing and direct heat sealing. Each has its pros and cons. Band seals are great for high-volume jobs but may not suit delicate items. Direct heat sealing offers precision, but it can be slower. Experimenting with both methods can clarify which suits your needs best.

Equipment considerations are crucial. The type of shrink wrap and its thickness influence sealing performance. Sometimes, the initial investment in better machines pays off in increased productivity. Reflect on your choices; you might need to fine-tune your setup to find the best fit. Don't rush the decision—testing different options might uncover better solutions.

Selecting the right shrink wrap for your products involves careful consideration of cost-effectiveness. Manufacturers often present various options, each with different price points. A lower-cost shrink wrap might seem appealing, but does it provide sufficient protection? Sometimes, investing slightly more could save you money in the long run by reducing product damage during shipping.

When assessing suppliers, it’s crucial to evaluate their reliability. Is their shrink wrap durable? Does it meet your specific needs? Take time to ask for samples. Run tests to check compatibility with your products. Consider the shipping environment as well. A supplier may offer competitive pricing but lacks consistency in quality. Reflect on whether the initial savings are worth potential headaches later.

Exploring customized shrink wrap can also be beneficial. Tailored solutions might fit your packaging better and enhance product visibility. However, these may come at a higher cost. It’s important to weigh the benefits of standout packaging against your budget constraints. Every business faces decisions about trade-offs. Balancing aesthetics with functionality will ultimately impact your brand’s reputation.