In today's fast-paced market, the role of shrink wrap packaging has become increasingly essential. According to a report by Smithers Pira, the global shrink film market is projected to reach $11 billion by 2026. This rapid growth underscores the importance of selecting the right solutions for various packaging needs.

Expert in packaging solutions, Dr. Emily Thompson, emphasizes, "Shrink wrap packaging offers unparalleled protection and versatility." This form of packaging not only preserves products but also enhances their visual appeal. Many businesses, however, struggle to find the right materials and technologies that suit their unique requirements.

The challenges in shrink wrap packaging can lead to inefficiencies and potential waste. Companies must address these issues to optimize their packaging processes. Evaluating options like biodegradable films and advanced sealing technologies can make a significant difference. In this competitive landscape, choosing the best shrink wrap packaging solution is crucial for maintaining product integrity and ensuring customer satisfaction.

Shrink wrap packaging has become a crucial tool across various industries. It offers durability and protection for products. Research indicates that the global shrink wrap market is expected to reach over $10 billion by 2026. This growth is driven by the demand for efficient packaging solutions.

One significant advantage of shrink wrap is its ability to prevent damage during shipping. According to industry studies, products wrapped in shrink film can have a 20% lower incidence of damage compared to those without. Additionally, shrink wrap is lightweight, which helps to reduce shipping costs. However, its environmental impact raises questions. While it aids in product preservation, the disposal of plastic wrap is a challenge for sustainability.

Shrink wrap also provides excellent visibility. Customers appreciate seeing the product before purchase. Clear shrink films allow for branding without obscuring the item. Yet, not all businesses utilize shrink wrap effectively. Some may overlook the importance of selecting the right thickness or type of film. Choosing the wrong material can lead to complications. A thoughtful approach is essential in maximizing the benefits of shrink wrap packaging.

When selecting shrink wrap materials, it's crucial to understand their different types and applications. Polyolefin (POF) shrink wrap is a popular choice. It is durable and provides a professional appearance. POF is often used for bundling products or packaging for retail sale. According to a report by Smithers Pira, the global shrink wrap market is expected to grow by 4.6% annually, driven by increased demand for durable packaging solutions.

PVC shrink wrap is another common option. It's known for its clarity and strength. It is ideal for securing items together without losing visibility. However, PVC can be less eco-friendly, which raises concerns among environmentally conscious consumers. A study from Freedonia Group highlights a strong shift toward sustainable packaging materials, pushing alternatives like biodegradable films into the spotlight.

There are also specialty shrink films, like cross-linked shrink wrap. These films offer superior performance under extreme conditions. They are often used in industrial applications. Nevertheless, these materials can be cost-prohibitive for smaller businesses. Evaluating budget constraints alongside functionality is essential. Despite the variety available, selecting the right type requires careful consideration of the project's specific needs.

Choosing the right shrink wrap equipment can be challenging. There are many factors to consider. Your business needs may vary greatly, which adds to the complexity. It’s essential to evaluate your products. Consider their shapes, sizes, and quantities. Not all equipment handles all products well.

Automation is a crucial factor. Manual machines may suffice for small operations. However, as demand increases, automated systems could improve efficiency. High-speed options can reduce labor costs and speed up the packaging process. Yet, they often require higher initial investments. You must weigh these costs against potential savings.

Take time to reflect on your specific operational needs. Sometimes, businesses overlook maintenance requirements. A machine that seems perfect might have high upkeep costs. It's important to ensure that any equipment aligns with your workflow. Choosing the wrong equipment can lead to delays. Flexibility is key. Your business might grow, and so should your shrink wrap capabilities. Find a balance that fits your unique needs.

| Equipment Type | Film Type | Output Capacity (units/hour) | Key Features | Price Range |

|---|---|---|---|---|

| Semi-Automatic Shrink Wrapper | Polyolefin | 30-50 | User-friendly, Adjustable speed | $2,500 - $5,000 |

| Fully Automatic Shrink Wrapper | PVC | 70-120 | High-speed, Integrated seal technology | $10,000 - $25,000 |

| Shrink Tunnel | Polyethylene | 50-100 | Even shrinkage, Adjustable temperature | $5,000 - $15,000 |

| Tabletop Shrink Wrapper | Cross-linked Polyolefin | 20-30 | Compact design, Ideal for small batches | $1,200 - $3,000 |

| Handheld Heat Gun | Various | N/A | Portable, Easy to use | $100 - $500 |

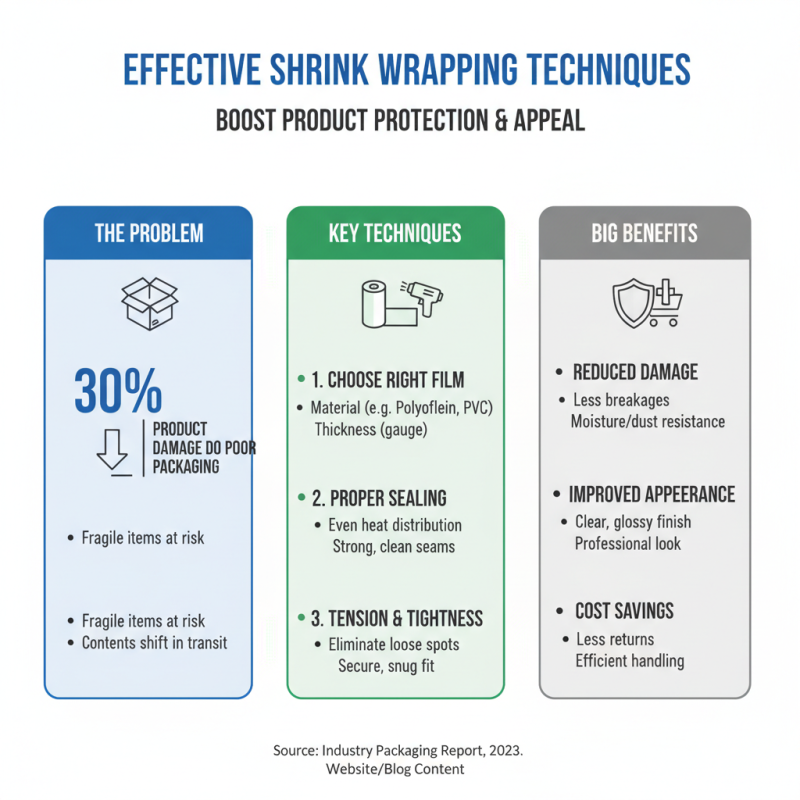

Effective shrink wrapping techniques play a crucial role in packaging solutions. According to a recent industry report, nearly 30% of products damaged in transit are attributed to inadequate packaging. This highlights the importance of using the right shrink wrap materials and methods. A well-wrapped product reduces the risk of physical damage and enhances shelf appeal.

One main technique involves optimal temperature control during the shrinking process. If the heat is uneven, it can lead to unsightly wrinkles or even burns on the wrap. A study revealed that 70% of packaging failures stem from improper heating. Additionally, maintaining a clean workstation prevents contaminants. Dust or debris under the wrap can weaken its integrity.

Experimenting with various types of shrink films also has its benefits. Polyolefin is popular for its clarity, while PVC offers excellent sealing properties. Yet, companies often fail to conduct proper material tests before large-scale production. A mistake in material choice can lead to increased waste and higher costs. A balance between cost-effectiveness and performance is essential, yet often overlooked.

As we look toward 2026, shrink wrap packaging solutions will witness significant innovations. Sustainability will be a core focus. Companies are poised to adopt eco-friendly materials. These materials will minimize environmental impact while maintaining effectiveness. Consumers are becoming increasingly aware of packaging waste. They prefer brands that prioritize sustainability.

Efficiency in shrink wrap processes will be crucial. Automation technologies could save time and reduce labor costs. Smart technologies might monitor packaging conditions. This data can inform decisions and improve product safety. Simple changes can make a big difference in efficiency.

**Tips:** Consider investing in machines that offer flexibility. They adapt to various packaging sizes. Regularly review your packaging strategy. Stay updated on the latest trends. Design plays an important role, too. A well-designed package attracts attention. Yet, it should remain easy to open. Balancing aesthetics and functionality can be challenging but rewarding.