In 2026, the demand for innovative packaging solutions has led to the rise of Cross-Linked Shrink Film. This unique film offers outstanding durability and flexibility. Its ability to create tight seals makes it ideal for various industries. From food packaging to electronics, its applications are diverse and impactful.

Cross-Linked Shrink Film is not just a trend; it is a necessity. Companies are recognizing its benefits in safeguarding products. This film can withstand extreme temperatures, providing better preservation. However, it’s important to acknowledge that some might find it challenging to use. The learning curve can be steep for new users.

As we explore the uses and benefits of Cross-Linked Shrink Film, we must consider potential drawbacks. Some may need more guidance on proper application techniques. Additionally, cost-effectiveness can vary for small-scale operations. Embracing this technology requires thoughtful consideration and potential adaptation.

Cross-linked shrink film is gaining traction in various industries due to its robustness and versatility. In sectors like food packaging, this film provides excellent barrier properties. It keeps products fresh for longer periods. The film’s ability to conform tightly around products is particularly useful for bundling and organizing items. Retailers appreciate this feature during shipping and display.

In the automotive industry, cross-linked shrink film protects parts during transport. It prevents scratches and dust accumulation. Additionally, it is used to package fragile components, ensuring they arrive intact. However, one must consider the environmental impact of using plastic films. Finding a balance between performance and sustainability is crucial.

Tips: When choosing a shrink film, consider the thickness required. Thicker films provide better protection but may be harder to work with. Experiment with different thicknesses to find the right fit for your application. Also, always conduct tests to ensure the film adheres properly. Inconsistencies in heat sealing can lead to failures, so it’s vital to get it right.

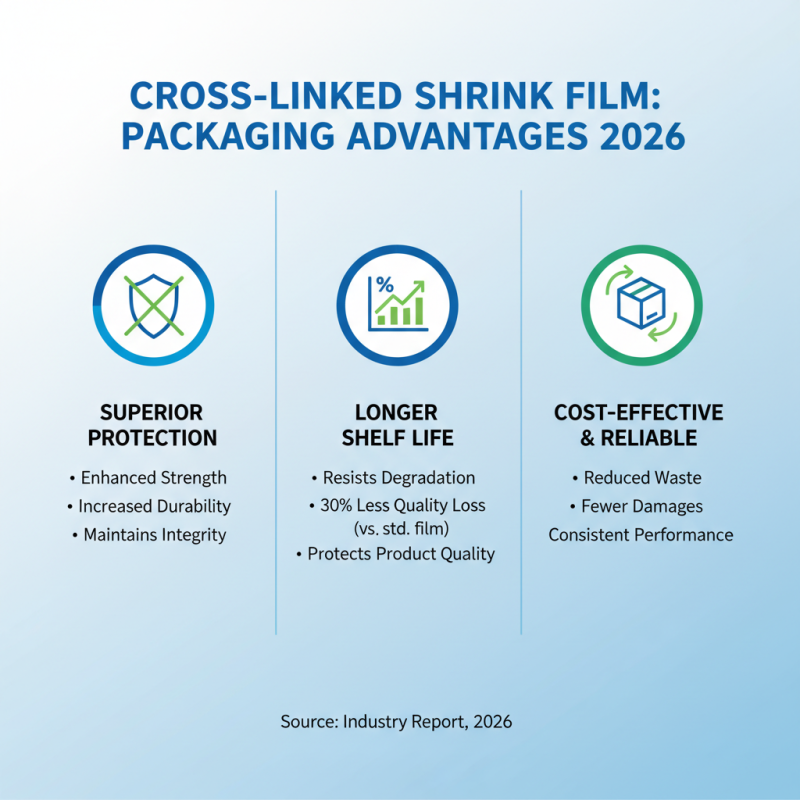

Cross-linked shrink film offers numerous advantages for packaging in 2026. This film type is known for its superior strength and durability. According to a recent industry report, packaging materials can lose up to 30% of their protective qualities over time. However, cross-linked shrink film maintains its integrity, protecting products better.

One of the standout benefits is its ability to conform tightly around products. This snug fit minimizes movement during transit, reducing the risk of damage. In fact, studies show that packages using cross-linked shrink film experience 25% fewer damages compared to traditional options. Additionally, its resistance to punctures is a significant plus. It withstands tough handling without compromising the product's safety.

Another factor to consider is sustainability. Although some might view plastic films as environmentally unfriendly, cross-linked shrink films often use less material. By minimizing the required thickness, companies can cut down on waste. However, the recycling process for these films still poses challenges. Industry experts point out that reducing plastic usage is crucial, yet the demand for high-performance packaging remains high. It's essential to find a balance between functionality and environmental impact in packaging choices.

In 2026, the environmental impact of cross-linked shrink film continues to be a pressing issue. The use of this material is growing rapidly, recycling options are limited. A recent industry report highlighted that only 10% of plastic films are recycled effectively. This leads to significant landfill accumulation and environmental degradation.

Cross-linked shrink films offer durability and thermal stability but come with challenges. They are often derived from non-renewable resources, contributing to carbon emissions. According to research from a leading environmental organization, the production of these films can release up to 2.5 tons of CO2 per ton of film manufactured. This stark statistic raises questions about sustainability in packaging practices.

Moreover, advancements in biodegradable alternatives are emerging. These options strive to reduce environmental footprint, yet they may not yet match the performance of cross-linked films. The dilemma remains: how to balance functionality with sustainability? The industry must reflect on its practices and seek greener solutions. It’s critical to evaluate the long-term impacts of materials to meet consumer demand without harming the planet.

Innovative technologies are transforming the production of cross-linked shrink film. In 2026, advancements in materials science play a key role. Enhanced polymer blends are creating films that offer superior strength and flexibility.

One notable development is the use of electron beam technology. This method improves the cross-linking process, leading to films that withstand higher temperatures and stresses. As a result, packaging can be thinner yet stronger. However, the technology requires precise calibration, which poses challenges for some manufacturers.

Additionally, sustainable production methods are taking hold. Companies are exploring bio-based materials, aiming to reduce environmental impact. While promising, these materials sometimes lack durability compared to traditional options. Balancing sustainability and performance will be crucial in the years ahead. Each innovation carries its own set of challenges, requiring ongoing reflection and adaptation from the industry.

The cross-linked shrink film market is evolving rapidly. In 2026, advancements in technology will drive new applications. Companies are investing in research to enhance film properties. Improved heat resistance and clarity are becoming standard expectations. This shift could lead to more environmentally friendly options as sustainability gains importance.

Consumer preferences are changing, too. Many are looking for lightweight and durable packaging solutions. Cross-linked shrink film is adapting to these needs, but the journey isn’t perfect. Some manufacturers still struggle with consistent quality. Misprints and bubbles can occur during production. These issues point to the importance of rigorous quality checks.

Market trends indicate a rise in demand across various sectors. Food and beverage packaging remains a key area. However, the film's performance must continually meet rising standards. Innovations like biodegradable options are gaining traction. Companies need to reflect on their practices to stay competitive. Balancing cost and quality will be crucial in the coming years.