In today's competitive marketplace, businesses are constantly seeking innovative solutions to enhance their packaging processes while ensuring product protection and sustainability. One such solution that has gained significant traction is the Shrink Packaging Machine. This technology not only helps streamline operations but also offers a myriad of benefits that can transform the way products are packaged and presented to consumers.

Utilizing a Shrink Packaging Machine allows businesses to efficiently wrap products in a variety of materials, providing an airtight seal that safeguards goods from dust, moisture, and physical damage. Furthermore, the use of this machinery can lead to more cohesive branding and professional presentation, which is crucial in attracting customers. As we delve into the top ten benefits of implementing shrink packaging in your business operations, it becomes evident that this is not just a capital investment but a strategic move towards enhancing product integrity and customer satisfaction.

Shrink packaging machines provide businesses with a powerful solution to enhance product protection. By encasing items in a tight, transparent plastic film, shrink packaging effectively shields them from environmental factors such as dust, moisture, and contaminants. This is particularly beneficial for products that require a sterile environment or are sensitive to changes in temperature and humidity. The snug fit offered by shrink packaging reduces the risk of damage during transportation and handling, ensuring that products arrive at their destination in pristine condition.

Additionally, shrink packaging serves as a deterrent against tampering and theft. The secure seal around the product makes it evident if an item has been compromised, instilling confidence in customers about the integrity of the product. This level of protection not only safeguards the physical item but also enhances brand reputation by demonstrating a commitment to quality and customer satisfaction. As businesses aim to create a reliable shopping experience, utilizing shrink packaging can significantly elevate the perceived value of their products while also minimizing returns associated with damages.

Shrink packaging machines play a crucial role in improving shelf life and preserving the freshness of products across various industries. According to a report by MarketsandMarkets, the global shrink packaging market is projected to grow from $18.81 billion in 2020 to $28.1 billion by 2025, highlighting the increasing demand for more effective preservation methods. The utilization of shrink films creates a tight barrier around products, which significantly reduces the permeability of moisture and oxygen, key factors that lead to spoilage. By minimizing exposure to these elements, businesses can prolong the shelf life of perishable goods, such as food items, while maintaining their original flavor, texture, and nutritional value.

Furthermore, shrink packaging not only aids in extending product freshness but also enhances overall presentation and product integrity. A study conducted by the Flexible Packaging Association noted that products packaged with shrink technology can experience up to a 50% reduction in damage during transit, an essential aspect for retailers and suppliers alike. This superior protection ensures that customers receive items in prime condition, reflecting positively on brand reputation and customer satisfaction. As the industry evolves, more companies are embracing shrink packaging solutions, understanding that improved shelf life and product preservation are vital components in today’s competitive market landscape.

| Benefit | Description | Impact on Business |

|---|---|---|

| Improved Shelf Life | Shrink packaging helps to seal products securely, preserving their freshness and preventing spoilage. | Reduces waste and increases customer satisfaction due to better quality products. |

| Cost Efficiency | Uses less material than traditional packaging methods, decreasing overall packaging costs. | Increases profitability by reducing material costs. |

| Protection Against Contamination | Seals products tightly, providing a barrier against dust, moisture, and other contaminants. | Enhances product quality and safety for consumers. |

| Enhanced Product Presentation | Shrink packaging provides a professional appearance, making products more visually appealing. | Improves brand image and attracts more customers. |

| Space-Saving | Compact shrink-wrapped items can save storage space. | Optimizes warehouse efficiency and reduces storage costs. |

| Convenience of Use | Shrink packaging machines are user-friendly and can be operated with minimal training. | Increases workflow efficiency with quicker packaging processes. |

| Versatility | Suitable for a wide range of products, from food items to electronics. | Allows businesses to package different product types effectively. |

| Eco-Friendliness | Many shrink films are recyclable, providing a more sustainable packaging option. | Enhances corporate responsibility and attracts environmentally conscious consumers. |

| Tamper Evidence | Shrink packaging can include tamper-evident seals, enhancing product safety. | Builds consumer trust and mitigates legal risks. |

| Improved Shipping | Shrinking wraps protect products during transit, reducing damage. | Lowers return rates and improves customer satisfaction. |

Shrink packaging has emerged as a cost-effective solution for businesses seeking to enhance their operations while minimizing expenses. By utilizing a shrink packaging machine, companies can significantly reduce their packaging costs. This method often requires less material compared to traditional packaging techniques, which means lower material expenses. Additionally, the efficiency of shrink wrapping can lead to savings on labor costs as it automates the packaging process, allowing businesses to allocate their workforce to other critical tasks.

Moreover, shrink packaging contributes to improved product protection during transit. The tight seal created by the shrink wrap keeps products safe from moisture, dust, and damage, reducing the likelihood of returns or replacements. This not only saves money on potential loss but also enhances customer satisfaction, leading to repeat business. The versatility in shrink packaging allows for various product shapes and sizes, further maximizing the utility of the materials used and ensuring that businesses can cater to diverse market demands without incurring excessive costs.

In today’s competitive business landscape, efficiency is paramount, especially in packaging operations. The implementation of a shrink packaging machine can significantly streamline processes, resulting in enhanced operational productivity. According to a report by Smithers Pira, the global market for shrink packaging is projected to grow by 4.2% annually, reflecting the rising demand for efficient packaging solutions across various industries. This growth is attributed to the ability of shrink packaging machines to minimize material use while maximizing product protection, which not only reduces costs but also shortens packaging times.

Furthermore, integrating shrink packaging systems can lead to substantial labor savings. A study by the Freedonia Group indicates that automated packaging solutions, such as shrink wrap machines, can cut labor costs by up to 30%. This reduction is largely due to the speed at which these machines operate—capable of packaging hundreds of products per hour with minimal manual intervention. By effectively automating the packaging process, businesses can repurpose labor for more critical tasks, thereby enhancing overall workforce productivity. Additionally, the consistent quality offered by shrink packaging machines ensures that products are packaged uniformly, leading to reduced product damage and waste, further contributing to operational efficiency.

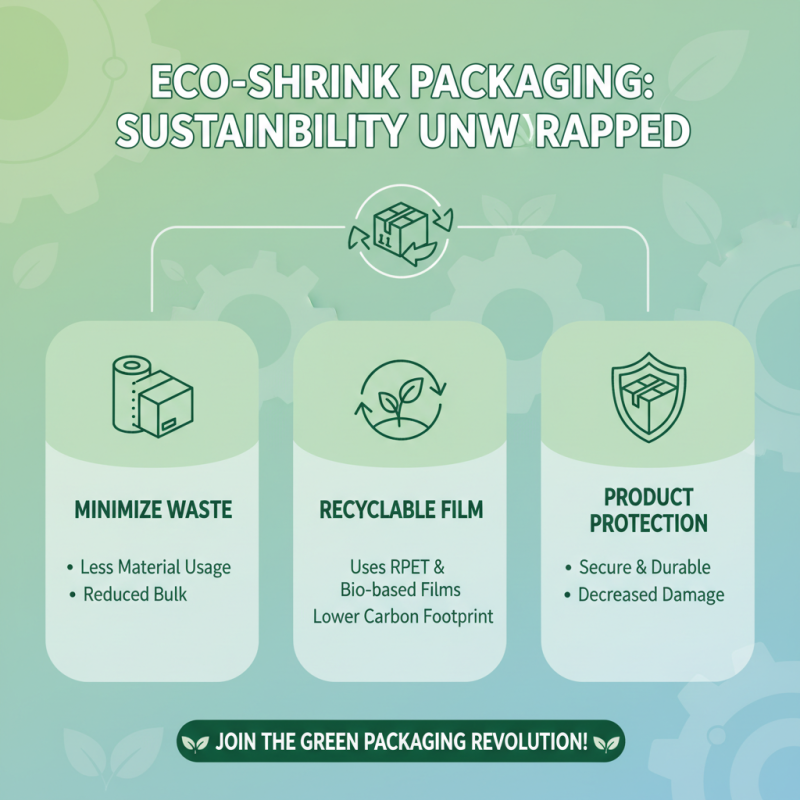

Shrink packaging technology has emerged as a highly effective eco-friendly solution for businesses looking to enhance their sustainability practices. By using a shrink packaging machine, companies can minimize their material usage while ensuring products are securely packaged. This technology often utilizes recyclable films that reduce the overall environmental impact, making it a popular choice among environmentally conscious brands.

One key benefit of shrink packaging is its ability to reduce waste. The materials used in shrink wrapping are typically thinner compared to traditional packaging, allowing businesses to save on resources without compromising quality. This not only helps reduce landfill contributions but also cuts down on shipping costs due to lower weight. Implementing this technology can provide a distinct competitive edge in a market increasingly focused on environmental responsibility.

**Tips:** When transitioning to shrink packaging, consider investing in biodegradable or recyclable films to further boost your eco-friendly image. Additionally, assess your packaging process to optimize efficiency and reduce excess material wastage. Regularly reviewing and updating your packaging practices can lead to continual improvements in sustainability efforts.