In the modern packaging industry, the significance of durable, efficient solutions cannot be overstated. According to Dr. Emily Carter, a leading expert in polymer technology, "Cross-Linked Shrink Film offers unparalleled benefits in both product protection and aesthetic appeal." This innovative material has gained traction for its superior strength and versatility, making it a go-to choice for various applications across multiple sectors.

Cross-Linked Shrink Film is not just a trend; it represents a paradigm shift in how products can be packaged and presented. Its unique properties allow for a snug fit around items, providing robust protection against physical damage while enhancing shelf visibility. Moreover, its resistance to puncturing and tearing ensures that products remain secure throughout the supply chain. As industries strive for sustainability and efficiency, adopting materials like Cross-Linked Shrink Film becomes essential for meeting both consumer demand and regulatory standards.

As companies increasingly focus on optimizing their packaging processes, understanding the advantages of Cross-Linked Shrink Film is critical. From improved brand representation to significant cost savings in material usage, the benefits are substantial. This article will delve into the top advantages of utilizing Cross-Linked Shrink Film for packaging solutions, shedding light on why it is favored by industry professionals and how it can transform packaging strategies.

Cross-linked shrink film has emerged as a superior choice for packaging solutions, offering a plethora of advantages that make it a favorite among manufacturers and vendors alike. One of the primary benefits is its enhanced durability. The cross-linking process increases the film's resistance to punctures and tears, ensuring that products are securely protected during transit and storage. Moreover, this type of film provides excellent clarity and gloss, which not only enhances the visual appeal of packaged goods but also helps to maintain the integrity of the product it encases.

When considering packaging options, it's essential to weigh efficiency alongside sustainability. Cross-linked shrink film is designed to use less material compared to traditional films, leading to reduced waste. This is particularly important in an era when consumers are increasingly valuing eco-friendly practices. Additionally, the thermal properties of cross-linked films allow for lower shrink temperatures, resulting in energy savings during the packaging process.

Tips: For businesses looking to maximize the benefits of cross-linked shrink film, it’s advisable to conduct a thorough evaluation of your packaging needs. Consider the specific characteristics of your products—size, shape, and fragility—to determine the most effective application of shrink film. Additionally, investing in a quality shrink wrap machine can enhance production efficiency, ultimately benefiting your bottom line.

Shrink film has become an essential material in the packaging industry, thanks to its ability to offer enhanced durability and protection. The cross-linked variety of shrink film is particularly noteworthy, as it undergoes a chemical process that significantly improves its strength and resilience. This superior durability means that products packaged with cross-linked shrink film are better equipped to withstand the stresses of transportation and handling, reducing the risk of damage during shipment.

Moreover, the protective qualities of cross-linked shrink film extend beyond simple physical sturdiness. This type of shrink film provides an effective barrier against moisture, dust, and other environmental factors that could compromise product integrity. As a result, items remain in optimal condition from the point of packaging through to the end-user, which is especially vital for sensitive or perishable goods. The use of cross-linked shrink film not only enhances product longevity but also reinforces brand reputation by ensuring customer satisfaction through the delivery of high-quality, well-preserved products.

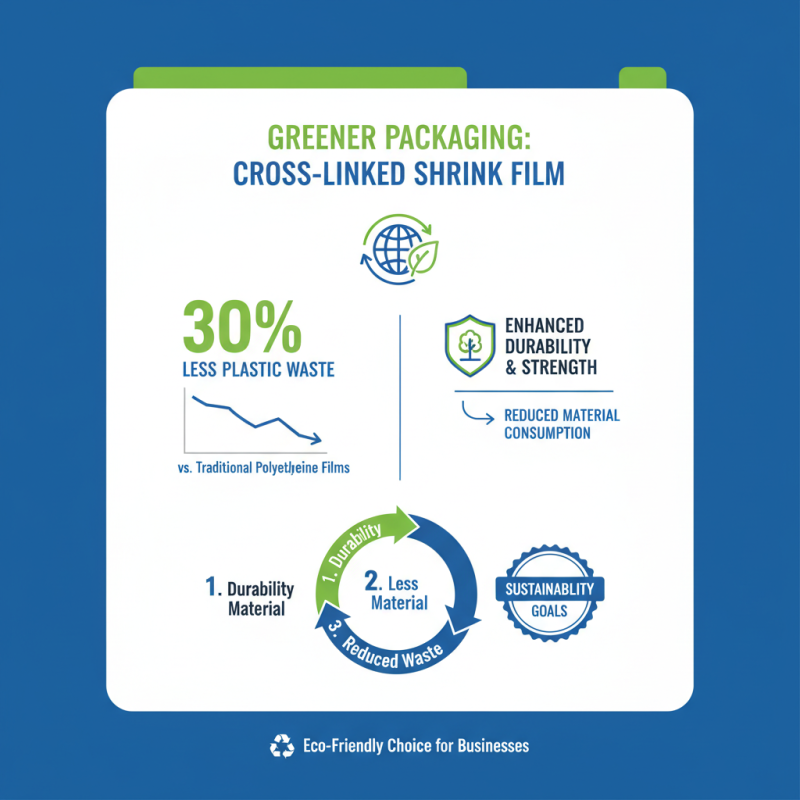

Cross-linked shrink film is becoming an increasingly popular choice for businesses seeking environmentally friendly packaging solutions. One of the key environmental advantages of cross-linked shrink film is its enhanced durability and strength, which can lead to reduced material consumption. Industry reports indicate that using cross-linked shrink film can decrease the amount of plastic waste by up to 30% compared to traditional polyethylene films. This reduction is crucial in the ongoing battle against plastic pollution and helps companies meet their sustainability goals.

Moreover, cross-linked shrink films are often manufactured using advanced technologies that allow for lower energy consumption during production. According to a study by the European Plastics Converters Association, using cross-linked films can result in a 20% reduction in greenhouse gas emissions compared to their standard counterparts. These films not only ensure product protection but also contribute to a smaller carbon footprint, making them an attractive choice for ecologically-conscious businesses. By adopting such innovative packaging solutions, companies can comply with increasingly stringent environmental regulations while appealing to a growing demographic of environmentally aware consumers.

Shrink film has become an increasingly popular choice for packaging due to its

cost-effectiveness and versatility. Unlike traditional packaging materials,

cross-linked shrink film offers a unique blend of durability

and flexibility, allowing businesses to optimize their packaging processes while keeping costs down. The

production of shrink film is generally less expensive than other materials, which contributes to lower overall packaging expenses. Additionally,

the lightweight nature of shrink film reduces shipping costs, making it a smart choice

for businesses looking to improve their bottom line.

Moreover, the efficiency of shrink film extends beyond just its initial cost savings. Its ability to conform tightly to a variety of product

shapes ensures minimal wasted space during storage and transportation. This efficient use of space not only maximizes storage facilities

but also allows companies to optimize their supply chain logistics. The high-quality seal provided by cross-linked shrink film minimizes the

risk of damage to products, which leads to fewer returns and replacements, further enhancing its cost-effectiveness in the long run. By

integrating shrink film into their packaging solutions, businesses can achieve a balance between affordability and effective product protection.

Cross-linked shrink film has emerged as a powerful packaging solution, enjoying wide applicability across various industries such as food and beverage, pharmaceuticals, and consumer goods. According to a recent report by MarketsandMarkets, the global shrink film market is projected to reach USD 11 billion by 2027, driven by the increasing need for efficient packaging solutions. The durability and strength of cross-linked shrink film offer enhancements in product protection, ensuring that items remain intact during transit. This material is particularly popular in the food industry, where it not only extends shelf life but also preserves the freshness of products, thereby reducing food waste.

One of the standout features of cross-linked shrink film is its versatility. In the pharmaceutical sector, for instance, it is used for bundling and protecting sensitive items such as blister packs and vials, benefiting from its puncture resistance and ability to maintain integrity under varying temperatures. Moreover, this type of film can be customized for different applications, with varying thicknesses and finishes, making it a favored choice among manufacturers looking for tailored packaging solutions.

Tips: When selecting cross-linked shrink film, always consider the specific requirements of your industry, such as temperature resistance and potential exposure to humidity. Also, ensure to perform thorough testing for strength and clarity to maintain product visibility while offering robust protection. Emphasizing sustainability in your packaging choices can also appeal to environmentally conscious consumers, thus enhancing brand image.