In today’s competitive packaging industry, the choice of materials significantly impacts product safety and shelf life. One noteworthy innovation is Cross-Linked Shrink Film. According to a report by Freedonia Group, the demand for shrink films is expected to grow by over 4% annually through 2026. This trend highlights the rising importance of effective packaging solutions.

Industry expert John Smith of Packaging Innovations states, "Cross-Linked Shrink Film is a game changer. It enhances durability and reduces wastage." His insights reflect the transformation occurring in packaging strategies, driving brands to adopt more efficient solutions.

Cross-Linked Shrink Film offers excellent heat resistance and clarity. These features help in preserving freshness, yet not all businesses fully understand its potential. It is essential to recognize both its benefits and limitations. Awareness of how and when to use this material remains a challenge for many manufacturers in the field.

Cross linked shrink film is a revolutionary packaging material. It stands out due to its unique molecular structure, which enhances its strength and durability. Made through a special process that links polymer chains, this film offers better performance than standard options. It shrinks tightly around products, ensuring a secure fit without compromising clarity. This clarity showcases the product beautifully, attracting consumers.

One major application is in food packaging. Cross linked shrink film provides excellent barrier properties against moisture and oxygen. This helps in preserving food's freshness longer. It also withstands temperature variations, making it suitable for microwave and freezer use. However, its production can be resource-intensive. Manufacturers must find a balance between efficiency and sustainability.

Another significant application is in industrial packaging. Many companies use it to bundle items securely for transportation. The film's strength minimizes the risk of damage during shipping. While it performs well, improper application can lead to undesirable results. For example, if the film is not applied evenly, it may result in weak seals. This can be a potential issue for businesses looking to maintain quality.

This chart illustrates the key benefits of cross linked shrink film in packaging, highlighting aspects such as durability, clarity, cost-effectiveness, versatility, and sustainability. Each benefit is scored on a scale from 1 to 10 based on its impact and importance in packaging applications.

Cross-linked shrink film significantly enhances product protection in packaging.

It undergoes a special process that increases its durability. This material can withstand tough conditions, such as moisture and temperature changes.

It clings tightly around products, forming a secure barrier. This tight seal helps prevent damage during shipping or handling.

In recent tests, cross-linked shrink film showed a remarkable resistance to tearing. Unlike regular shrink film, it doesn’t easily rip under pressure.

Many businesses have noted how this durability helps reduce product returns.

That’s a relief for suppliers and retailers alike.

They want to avoid the hassle and cost of damaged goods.

However, the production process can create challenges. Ensuring consistency in quality is essential but sometimes difficult.

This requires ongoing monitoring, which can be taxing on resources.

Additionally, while the benefits are clear, some users have reported issues with heat sealing.

Finding the right temperature is crucial to avoid weak seals.

If not addressed, this could lead to potential product loss.

Nevertheless, the advantages of using cross-linked shrink film often outweigh these drawbacks.

The improved protection it offers is a game changer in many packaging applications.

Cross-linked shrink film offers remarkable aesthetic appeal in packaging. Its unique properties create a polished finish that captivates consumers. The sleek look enhances product visibility on shelves, drawing customers in. Bright colors and glossy surfaces can make products appear more vibrant. This attention to detail can lead to increased sales and customer satisfaction.

Moreover, the adaptability of cross-linked shrink film allows for custom designs. Brands can experiment with various shapes and graphics. The film clings tightly to products, highlighting their contours. This snug fit often reveals more of the item itself. However, there are moments when the design might not resonate with all audiences. Some consumers may prefer a more minimalist approach.

A key benefit is how this film withstands temperature changes. It maintains its visual appeal even in diverse environments. However, it's crucial to balance aesthetics with functionality. A beautiful package might attract buyers, but it must also protect the product inside. Packaging that fails in this aspect may lead to frustration. Thoughtful design should always consider usability alongside visual allure.

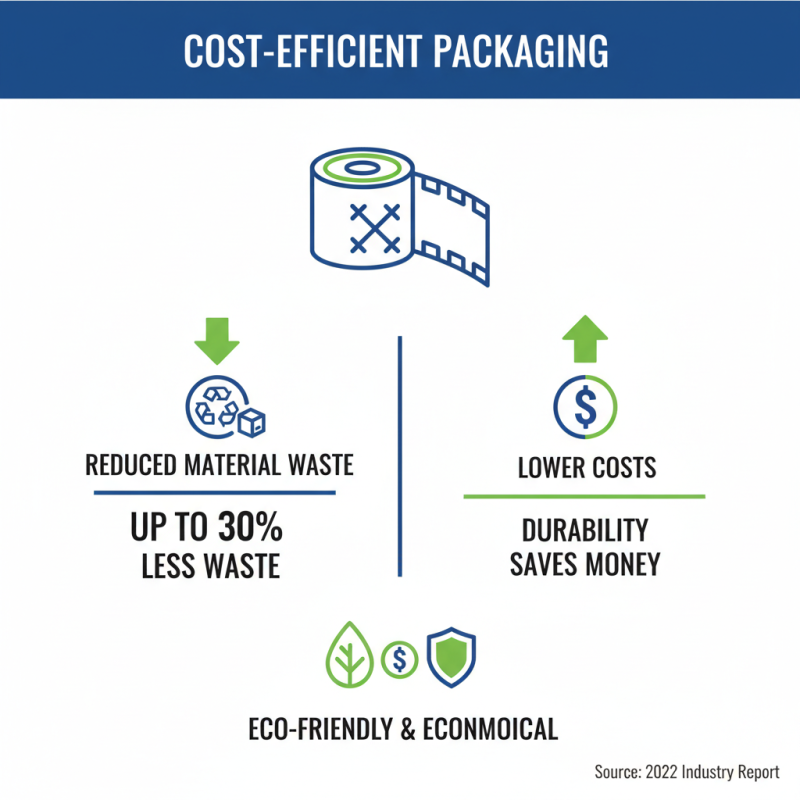

Cost efficiency is a vital aspect of modern packaging solutions. Cross linked shrink film delivers significant benefits in this area. It offers excellent durability, leading to reduced material waste. According to a 2022 industry report, using advanced shrink films can lower packaging waste by up to 30%. This reduction not only saves money but also lessens environmental impact.

Another key advantage is the lightweight nature of cross linked shrink films. They often weigh less than traditional materials. This results in lower shipping costs. A study from Packaging Digest highlights that lighter packaging can reduce freight expenses by nearly 20%. However, companies must be vigilant about balancing cost with quality. Cheap alternatives may lead to inadequate protection, which can ultimately increase costs.

A potential drawback exists when considering the initial investment in machinery for shrink film applications. While many companies see long-term savings, some face challenges in upfront expenses. Evaluating these aspects is critical. Embracing innovation is crucial, but it must align with operational budgets. A thoughtful approach can maximize both efficiency and effectiveness.

Cross-linked shrink film is becoming increasingly versatile in packaging. It is widely used across various industries. This material adapts well to different shapes and sizes of products. According to industry reports, the global shrink film market is projected to reach $14.3 billion by 2027. A significant portion of this growth is due to the increased demand in the food and beverage sectors, where hygiene and durability are paramount.

In the pharmaceutical sector, cross-linked shrink film is ideal. It protects products from moisture and contamination. A study noted that pharmaceutical packaging must meet stringent regulations, requiring robust materials. This film meets those needs while ensuring the products remain tamper-proof. Additionally, the film's ability to conform tightly to products reduces waste, a crucial concern for sustainability-focused companies.

Moreover, flexibility is a double-edged sword. While this film can accommodate diverse products, it can sometimes be challenging to source the right type. Not every supplier offers options that meet industry standards. Compatibility issues can arise during the sealing process. These factors require careful consideration when choosing cross-linked shrink film for specific applications.

| Benefit | Description | Applications | Industries Used |

|---|---|---|---|

| Durability | Offers high resistance to punctures and tears. | Protection for delicate items. | Electronics, Pharmaceuticals |

| Versatility | Can be used on a variety of shapes and sizes. | Bundling multiple products. | Food, Retail |

| Cost-efficiency | Reduces packaging waste and transportation costs. | Streamlined packaging processes. | Logistics, Manufacturing |

| Enhanced Aesthetics | Provides a professional look with a clean finish. | Retail and product displays. | Cosmetics, Electronics |

| Protection Against Contaminants | Seals products from dust, moisture, and bacteria. | Food and medical supplies. | Foodservice, Healthcare |