In the world of packaging, "Cross-Linked Shrink Film" has emerged as a game-changer. Experts like John Smith, a leader in the field, emphasize, “This film enhances durability and performance significantly.” As brands look for efficient solutions, the benefits of cross-linked shrink film become crucial.

This material offers exceptional strength and resistance to various environmental factors. It shrinks tightly around products, ensuring they remain secure. However, while the advantages are clear, understanding the application process is integral for optimal results. Users often face challenges when errors occur. It’s essential to focus on the right conditions during application.

Moreover, not all films are created equal. Some might struggle under specific temperatures or timelines. Users should reflect on their needs carefully. With proper insight, "Cross-Linked Shrink Film" can deliver unmatched results, transforming ordinary packaging processes into extraordinary ones.

Cross linked shrink films are transforming packaging solutions. They offer enhanced durability and clarity compared to traditional films. According to a 2022 industry report, the global shrink film market is expected to grow at a CAGR of 4.5% through 2030. This increase highlights the importance of choosing the right materials for effective packaging.

These films provide significant benefits such as improved resistance to punctures and tears. They also shrink uniformly during the application of heat. This property allows for a tight fit around products, ensuring they remain securely packaged. Furthermore, cross linked shrink films boast exceptional optical qualities, enabling clear visibility of the product inside. In fact, survey data reveals that 78% of consumers prefer packaging that displays the product clearly.

However, there are challenges to consider. Not all heat sources are compatible with cross linked films. Users may need to experiment to find the right settings for their specific applications. Additionally, while the material is durable, it can be harder to recycle compared to other packaging options. Reflecting on the trade-offs between durability and sustainability is crucial for users choosing packaging solutions.

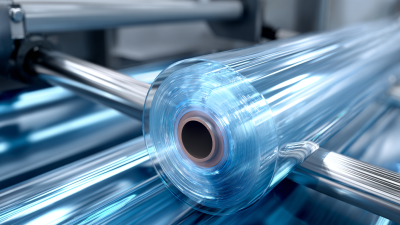

Cross-linked shrink film stands out in the packaging industry due to its unique properties. It is engineered through a process that enhances its molecular structure, making it more durable than traditional films. According to a recent industry report, cross-linked films exhibit 25% higher tensile strength. This means they can handle tough environments without tearing or breaking easily.

One of the key features of cross-linked shrink films is their superior shrinkage capability. They can shrink tightly around products, providing a snug fit that protects items from moisture and dust. This is especially critical in industries like food and pharmaceuticals, where packaging integrity is paramount. Additionally, these films offer enhanced clarity, which helps to showcase the product effectively.

Tips for users include ensuring proper temperature control during the shrinking process. Too high of a temperature can lead to inconsistencies. Another tip is to regularly check the film for any signs of wear before use, as even minor defects can impact performance. Users should document their shrink process adjustments to refine their techniques over time. Remember, if the product does not shrink properly, it can lead to damage or spoilage.

Cross linked shrink film has found a versatile application across various industries. In food packaging, it enhances product freshness and extends shelf life. Its strong barrier properties ensure that moisture and air are kept at bay. This is essential for maintaining quality and safety. In the pharmaceutical sector, the film protects medications from environmental factors, ensuring effectiveness.

Tips can help users maximize the benefits of cross linked shrink film. Ensure proper heat application during shrinking to avoid film wrinkling. Monitor the temperature closely for optimal results. Experiment with different materials to find the perfect match for your needs. In retail, use bright colors and patterns to attract customers. The visual appeal can significantly influence purchasing decisions.

In the industrial sector, cross linked shrink film is used for bundling products. It provides stability during transportation. However, testing for durability before large-scale adoption is crucial. Issues such as film breakage can arise without proper quality assessments. It’s essential to remain aware of these challenges and seek feedback from your team. This proactive approach can lead to improvements.

| Industry | Application | Benefits | Useful Tips |

|---|---|---|---|

| Food Packaging | Sealing meat and produce | Longer shelf life, improved freshness | Ensure proper heat application to avoid overwrapping |

| Electronics | Protection of circuit boards | Dust and moisture protection | Use anti-static options for sensitive items |

| Retail | Wrapping clothing and textiles | Enhanced presentation and protection | Consider branding practices with printed films |

| Industrial | Bundling and securing products | Stability during transport | Select the right strength for the load |

| Pharmaceutical | Packaging medical supplies | Compliance with health regulations | Ensure airtight sealing for sterile items |

Cross linked shrink film is versatile and popular in packaging. When using it, certain handling techniques can enhance results. First, ensure proper storage conditions. Keep the film away from direct sunlight and extreme temperatures. Too much heat or cold can impact its performance. Always check for any tears or defects before use. Damaged film can create problems during the shrinking process.

Proper application is crucial. Use a reliable heat source for effective shrinking. A heat gun or shrinking tunnel often works best. Monitor the temperature closely. Overheating can cause the film to bubble or melt. Be aware of the film's thickness; thicker films may require more time to shrink properly.

After shrink wrapping, inspect each package. Look for clear edges and tight seals. If there are loose areas, it may indicate an inadequate seal. Don't rush the process. Taking time ensures quality packaging. Experiment with different settings to find what works best. Reflection on previous attempts often leads to improved outcomes.

Shrink films are widely used in packaging due to their flexibility and strength. However, their environmental impact is significant. Many shrink films are made from polyethylene or PVC. These materials can take hundreds of years to decompose. This poses a challenge for sustainability and waste management.

Choosing eco-friendly alternatives can make a difference. Look for films made from recycled materials. Some films are even biodegradable. These options may reduce your environmental footprint. It's also wise to consider the production processes. Opt for manufacturers that prioritize sustainable practices.

Here are some tips for users: