In today's competitive packaging landscape, selecting the appropriate shrink film for your needs is paramount. The global shrink film market is expected to witness significant growth, reaching approximately $8 billion by 2025, according to a report by Market Research Future. This burgeoning market reflects the increasing demand across various industries, including food and beverage, pharmaceuticals, and consumer goods. With the rise of e-commerce and the necessity for enhanced product protection during transit, understanding the nuances of shrink film technology becomes essential for businesses aiming to optimize their packaging strategies.

Industry experts emphasize the importance of making informed choices in shrink film selection. John Doe, a well-regarded packaging consultant, states, "Choosing the right shrink film is not just about aesthetics; it's about ensuring product integrity and enhancing shelf life." This sentiment underscores the critical role that shrink film plays in not only securing products but also appealing to consumers who prioritize sustainability and quality. As manufacturers navigate the complexities of material options, film thickness, and sealing techniques, having a comprehensive guide can streamline the decision-making process and lead to more sustainable packaging solutions.

Shrink film is an essential packaging solution that comes in various types, each suited for specific applications. The most common types include centerfold, single wound, and tubing films. Centerfold shrink film is perfect for wrapping items with ease, as it is designed to open up when unrolled. Single wound films are ideal for larger products and those requiring high clarity and performance, while tubing films offer versatility for bundling items. Understanding these variations is crucial when selecting the right shrink film for your packaging needs.

When considering shrink film, it’s important to evaluate the end-use of your packaged products. Factors such as the size and shape of the items, the required clarity, and the conditions they will face during transit must be taken into account. Additionally, compatibility with your sealing equipment can influence performance.

Tips: Always conduct a test run with your chosen shrink film to ensure it adheres properly to your products and can withstand shipping conditions. Also, consider the environmental impact of your materials and explore eco-friendly options that might align with your sustainability goals. Ensuring that your shrink film meets your specific needs can enhance product protection and aesthetic appeal.

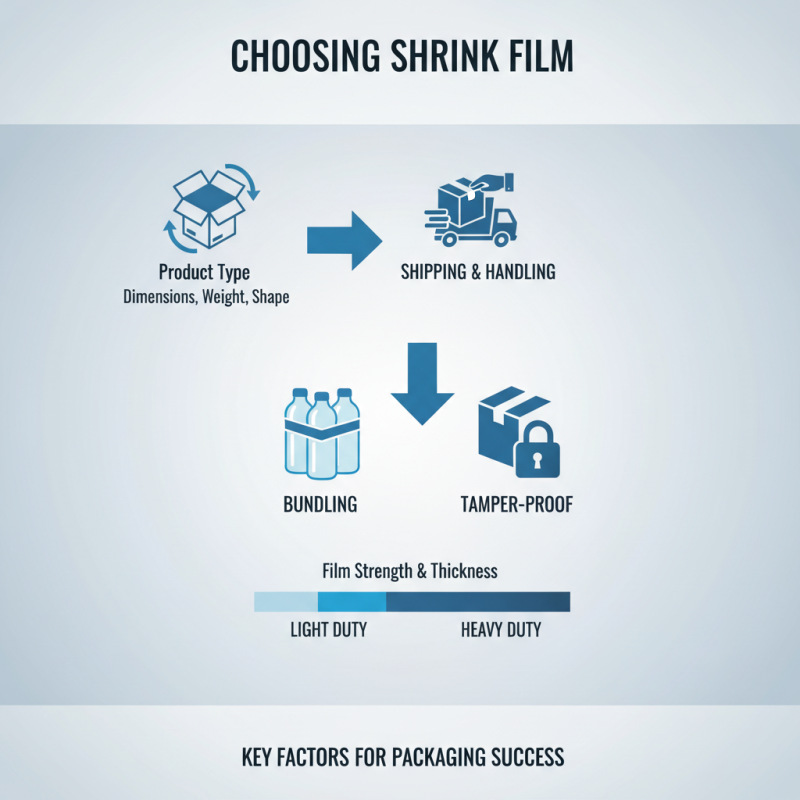

When selecting the right shrink film for your packaging needs, there are several key factors to consider. First, evaluate the type of product you are packaging. The dimensions, weight, and shape of the item will influence the choice of shrink film. Ensure the film has the necessary strength and thickness to withstand the demands of shipping and handling. Additionally, consider whether the film will be used for bundling products or creating tamper-proof seals, as this may affect the required material properties.

Tip: Always test the shrink film with your products before fully committing to it. This ensures compatibility and reduces the likelihood of damage during transit.

Another crucial factor is the shrinkage rate of the film. Different shrink films offer varying degrees of shrinkage when heat is applied. A higher shrink percentage can accommodate irregularly shaped products more effectively, while lower shrink rates might be suitable for standard shapes. Assess the shrink temperature as well, as some films require higher heat to achieve a tight fit.

Tip: Keep environmental impact in mind when selecting shrink film. Opt for materials that are recyclable or made from sustainable resources to reduce your ecological footprint.

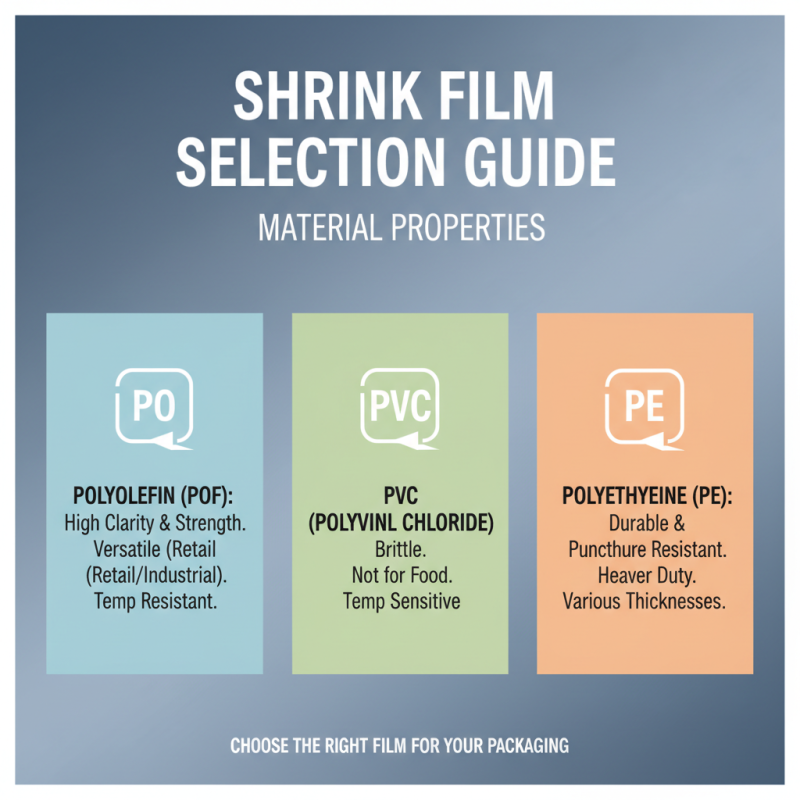

When selecting the right shrink film for your packaging needs, understanding the material properties of different films is crucial. Shrink films are commonly made from materials such as polyolefin, PVC, and polyethylene, each offering unique benefits and limitations. For instance, polyolefin films are versatile and boast a high clarity and excellent strength, making them suitable for both retail and industrial applications. They are also known for their resilience against temperature variations, which enhances their performance in various environments.

On the other hand, PVC shrink films are cost-effective and relatively easy to use, providing good shrink properties and clarity. However, they may not be as environmentally friendly as their polyolefin counterparts. In contrast, polyethylene shrink films are known for their ability to withstand impacts and their ease of sealing, but they typically offer lower clarity and aesthetics. Selecting the right type of shrink film ultimately depends on specific packaging requirements such as environmental considerations, cost-effectiveness, and desired visual appeal, making a thorough comparison of material properties essential before making a decision.

When selecting the right shrink film for packaging needs, evaluating cost-effectiveness and performance is crucial. Cost-effectiveness often dictates the feasibility of a project; thus, businesses must consider the initial investment against the potential savings in supply chain efficiency. A good starting point is to calculate not just the material cost, but also factors like yield, waste, and labor involved in application.

The right shrink film can drastically reduce expenses over time, especially if it integrates smoothly into existing production processes.

Performance metrics are equally important and should align with the specific requirements of the packaging application. Critical factors include shrink temperature, clarity, puncture resistance, and sealing strength. For products that need visibility, choosing a film with high clarity can enhance shelf appeal. Conversely, for heavier or sharp-edged items, films with greater puncture resistance are vital to ensure product protection throughout the distribution chain.

By closely analyzing both cost and performance characteristics, businesses can make informed decisions that optimize their packaging solutions.

When integrating shrink film into your packaging operations, it's crucial to follow best practices that ensure efficiency and product protection. One of the first steps is to select the appropriate type of shrink film based on the product specifications and the intended use. Consider factors such as the film's thickness, clarity, and shrink rate, as these influence the final appearance and durability of your packaging. Properly matching the film to the product can enhance shelf appeal while providing necessary protection during transit.

Tips: Always conduct compatibility tests between the film and the product before full-scale implementation. This can help you avoid potential issues such as inadequate sealing or excessive shrinkage that might compromise the integrity of the packaging. Additionally, keep an eye on external variables like temperature and humidity, as they can affect the shrinkage process.

Training your staff is equally important. Ensure that everyone involved in the packaging process understands the machinery involved and the specific requirements for using shrink film effectively. Regular maintenance of shrink wrap equipment will also improve performance and reduce downtime, leading to smoother operations. This preparation, coupled with regular quality checks, will ensure that your shrink film packaging not only meets but exceeds expectations.

| Film Type | Thickness (mil) | Shrink Ratio | Temperature Requirement (°F) | Applications |

|---|---|---|---|---|

| PVC Shrink Film | 50-75 | 40-50% | 250-325 | Bottles, Boxes, Multi-packaging |

| Polyolefin Shrink Film | 30-80 | 30-40% | 250-350 | Food Packaging, Electronics, Gifts |

| PET Shrink Film | 70-100 | 25-30% | 300-400 | High-end Products, Bottled Beverages |

| Cross-Linked Polyolefin | 40-60 | 40-60% | 275-350 | Industrial Packaging, Heavy-duty Applications |

| Biodegradable Shrink Film | 30-60 | 20-40% | 250-350 | Eco-friendly Packaging, Retail Items |